What We Learned from Using AGVs in Real Warehouse Operations

The use of Automated Guided Vehicles (AGVs) in warehouse operations has grown rapidly in recent years. While marketing materials often highlight ideal scenarios, real-world warehouse environments present unique challenges. This article shares practical insights gained from hands-on experience with AGVs in daily warehouse operations.

1. Realistic Expectations vs Reality

One of the biggest misconceptions is that AGVs immediately replace human labor. In reality, AGVs work best as collaborators. They handle repetitive transport tasks, while humans manage exceptions, decision-making, and supervision.

Successful warehouses treat AGVs as productivity tools, not full replacements.

2. Common Use Cases That Work Well

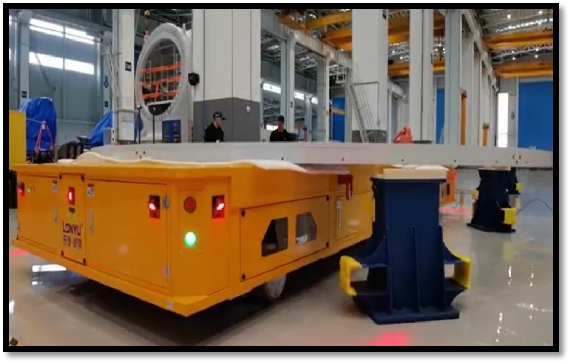

Based on real operations, AGVs perform best in:

- Point-to-point pallet transportation

- Production line feeding

- Finished goods movement to outbound areas

- Cross-docking operations

Highly dynamic tasks or frequent layout changes usually require more advanced navigation systems or hybrid solutions.

3. Real Challenges Encountered

Navigation and Localization

Even advanced navigation systems can struggle with crowded or constantly changing environments. Temporary obstacles and human behavior are major variables.

Network and Communication

Stable wireless connectivity is critical. Poor Wi-Fi coverage can cause delays or system interruptions, especially in large warehouses.

Human Acceptance

Operators and forklift drivers may initially resist automation. Clear communication and training significantly improve acceptance and cooperation.

4. Key Benefits Observed After Stabilization

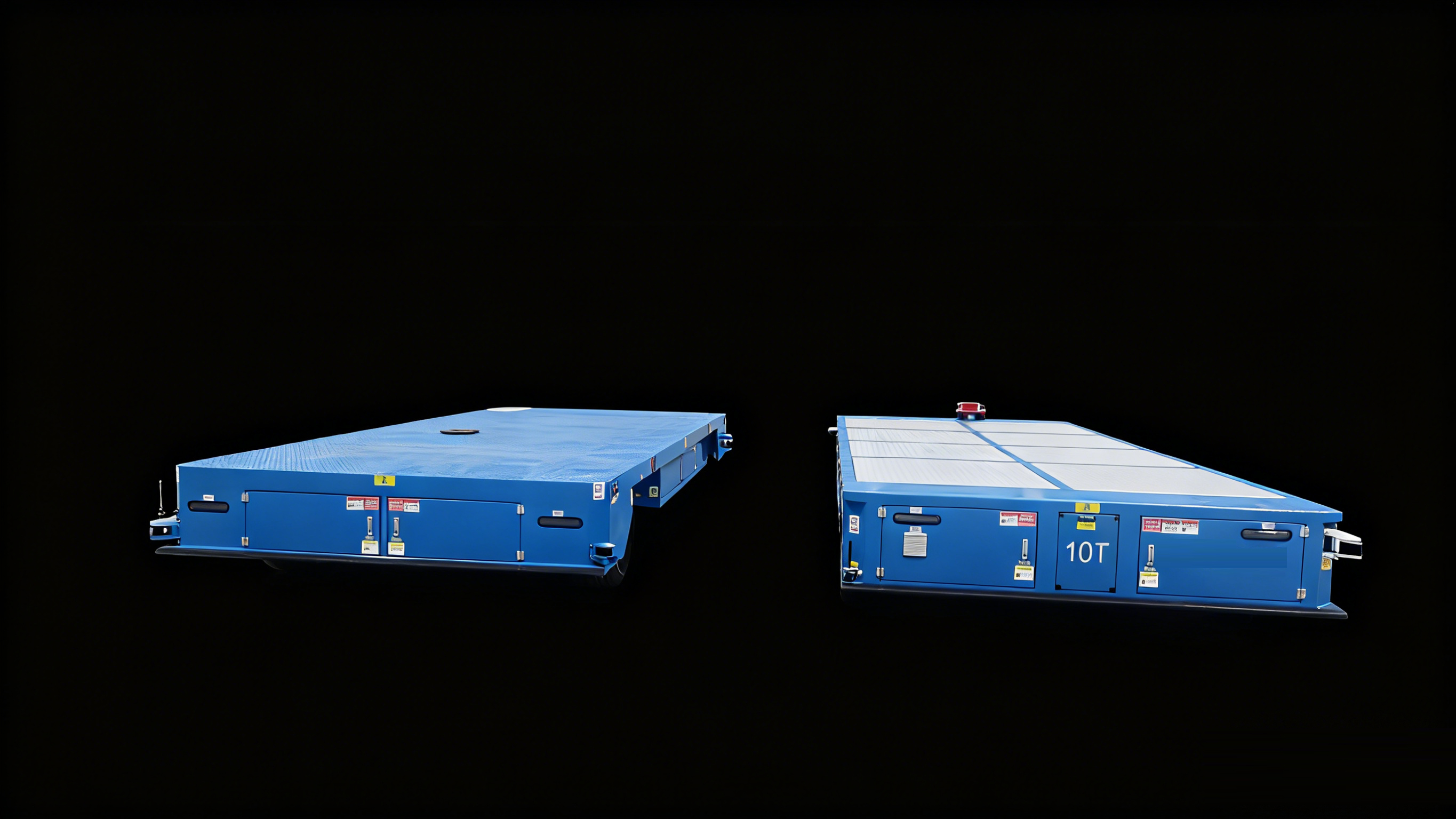

Once fully integrated, AGVs typically deliver:

- Predictable logistics flow

- Reduced product damage

- Better space utilization

- Improved safety compliance

Many warehouses also find it easier to scale operations by adding more AGVs instead of hiring and training new staff.

5. Final Thoughts

Real-world experience proves that AGVs are not a one-size-fits-all solution, but when correctly implemented, they provide long-term operational value. The most successful projects focus on system design, human collaboration, and continuous optimization rather than automation alone.