Real-World Experience Using AGVs in Warehouse Environments

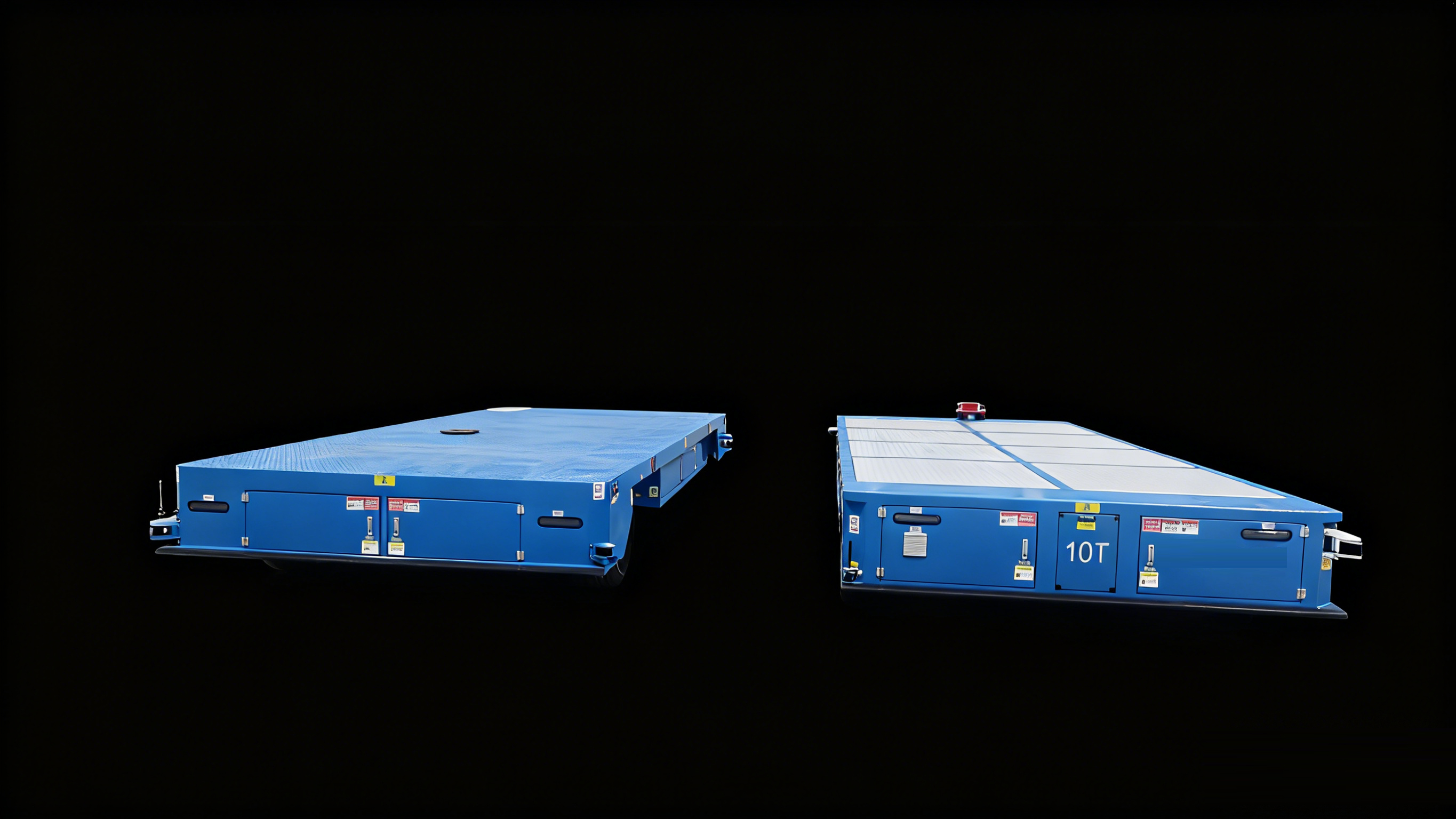

Automated Guided Vehicles (AGVs) are no longer experimental technology. In many modern warehouses, AGVs are already operating alongside human workers, moving pallets, transporting materials, and improving overall efficiency. However, real-world deployment often looks very different from what brochures and demos promise. This article shares practical experience using AGVs in real warehouse environments, including benefits, challenges, and lessons learned.

1. Why Warehouses Are Adopting AGVs

Warehouses face increasing pressure from labor shortages, rising costs, and faster delivery expectations. AGVs help solve these problems by:

- Reducing dependence on manual labor

- Providing predictable and repeatable material flow

- Improving safety by minimizing forklift traffic

- Supporting 24/7 operations

In practice, AGVs are most effective in repetitive transport tasks such as pallet movement between storage zones, production lines, and shipping areas.

2. Real Deployment Challenges in Warehouse Environments

2.1 Layout Limitations

Many warehouses were not originally designed for automation. Narrow aisles, uneven floors, and mixed traffic (people + forklifts + AGVs) often create navigation challenges. Successful deployments usually require minor layout adjustments or dedicated AGV lanes.

2.2 Environmental Factors

Dust, lighting changes, floor reflections, and temperature variation can all affect AGV sensors. In real-world use, sensor calibration and environmental testing become critical steps before full-scale operation.

2.3 Integration with Existing Systems

Connecting AGVs with WMS or ERP systems is often more complex than expected. Data synchronization, task scheduling, and exception handling require careful planning and testing.

3. Operational Benefits Observed in Practice

Warehouses that successfully deploy AGVs often report:

- 20–40% reduction in internal transport labor costs

- More stable throughput during peak seasons

- Lower accident rates compared to manual forklift operations

- Improved inventory accuracy due to system integration

AGVs also perform consistently across shifts, which helps stabilize warehouse output.

4. Lessons Learned from Real Projects

Based on real-world implementations, several best practices stand out:

- Start with a pilot zone instead of full automation

- Choose AGVs that can handle environmental variability

- Invest in staff training and change management

- Plan maintenance and remote diagnostics from day one

AGVs are not a “plug-and-play” solution; they are part of a long-term automation strategy.