Industrial AGV Solutions: Transforming Smart Manufacturing and Logistics

As industries worldwide adopt automation to improve efficiency, reduce operational costs, and enhance workplace safety, Industrial AGV solutions have emerged as a critical technology. AGVs (Automated Guided Vehicles) offer reliable, scalable, and intelligent material-handling capabilities that support modern production lines, warehouses, and distribution centers. This article explores how industrial AGV solutions work, their applications, advantages, and why they are essential for the next generation of smart factories.

What Are Industrial AGV Solutions?

Industrial AGV solutions refer to integrated systems that use automated guided vehicles to transport materials within industrial environments. These systems combine advanced navigation technologies, fleet management software, and intelligent sensors to ensure safe, efficient, and predictable material flow.

Industries use AGVs to automate tasks traditionally performed by forklifts, pallet trucks, and manual labor, improving consistency and reducing errors.

How Industrial AGVs Operate

Industrial AGVs rely on a combination of hardware and software technologies, including:

- Navigation systems (magnetic tape, laser guidance, QR codes, or SLAM)

- Safety sensors (LiDAR, cameras, ultrasonic detectors)

- Fleet management software (task scheduling, route optimization, real-time monitoring)

- Wireless communication (Wi-Fi or industrial networks for coordination)

These elements allow AGVs to move materials accurately, avoid obstacles, and perform tasks autonomously around the clock.

Types of Industrial AGVs

Different industries require different AGV types to meet specific operational needs:

1. AGV Forklifts

Used for pallet handling, stacking, loading, and high-bay storage.

2. Tugger AGVs

Pull carts or trailers for batch transportation across long distances.

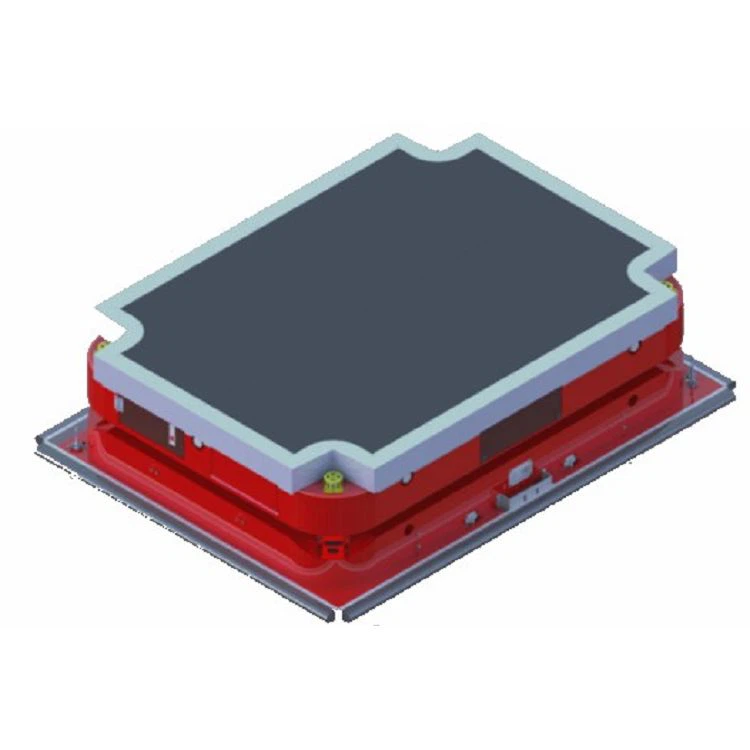

3. Unit Load AGVs

Equipped with conveyors or lift tables, ideal for moving boxes, trays, or components.

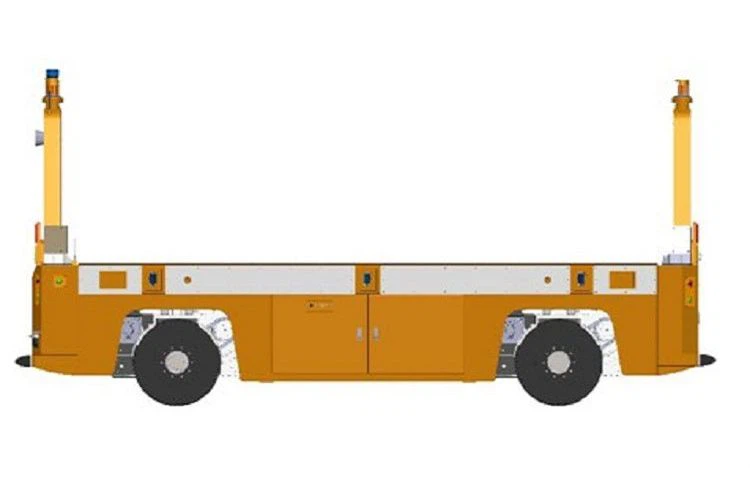

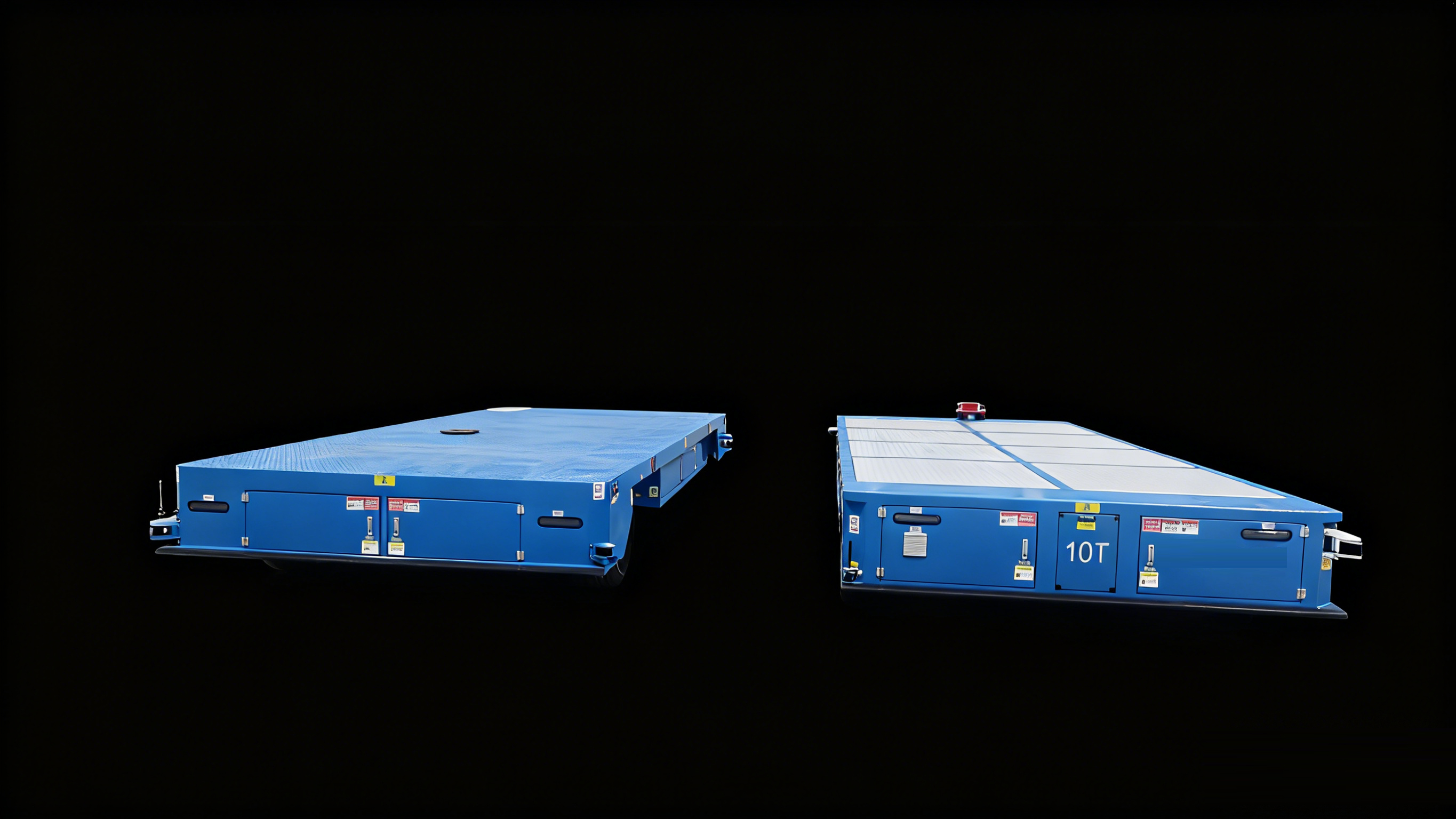

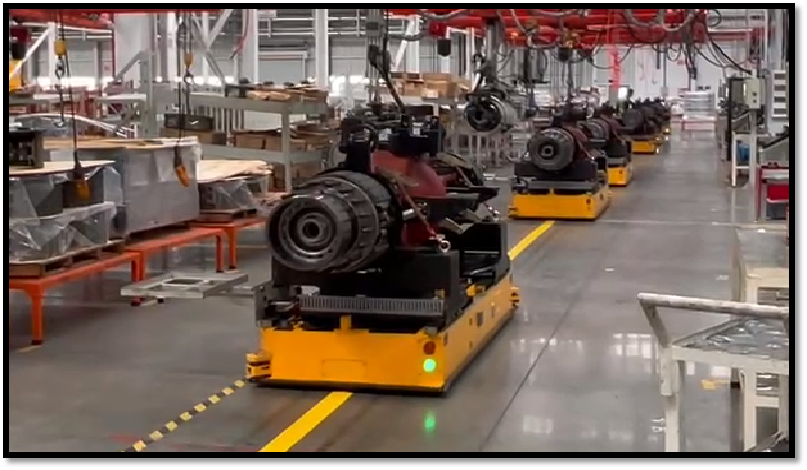

4. Heavy-Duty AGVs

Designed to transport oversized loads such as metal coils, dies, or large assemblies.

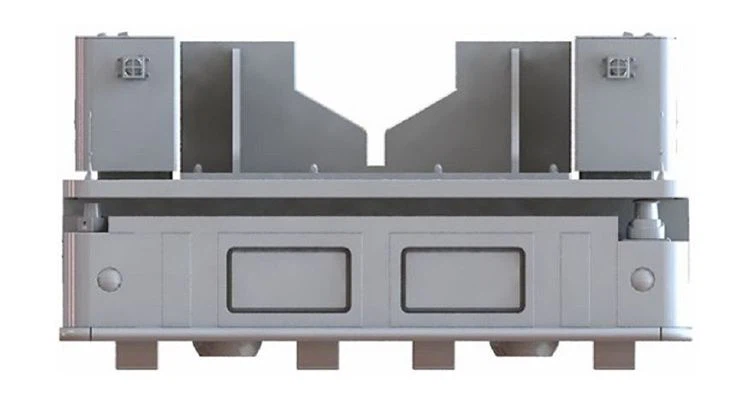

5. Customized AGVs

Tailored for unique industrial environments including automotive, electronics, food processing, and pharmaceuticals.

Key Benefits of Industrial AGV Solutions

1. Improved Efficiency and Throughput

Industrial AGVs work continuously without breaks, reducing cycle times and increasing operational speed.

2. Enhanced Workplace Safety

Onboard sensors and automated braking drastically reduce collision risks and accidents caused by manual forklifts.

3. Reduced Labor and Operational Costs

Automation lowers staffing requirements, reduces training costs, and minimizes human error.

4. Precision and Consistency

AGVs follow predefined routes and tasks with accuracy, ensuring stable material flow.

5. High Scalability

AGV fleets can grow as production demands increase, offering long-term flexibility.

6. Integration With Industry 4.0

Modern AGV solutions integrate with ERP, MES, and WMS systems to support smart, data-driven manufacturing.

Industrial Applications of AGV Solutions

AGVs are widely used in various industries, including:

- Automotive: Transporting components, engines, and assemblies

- Electronics: Moving circuit boards, modules, and sensitive components

- Metal Processing: Handling heavy coils, sheets, and machinery parts

- Food & Beverage: Maintaining hygienic, contamination-free logistics

- Pharmaceuticals: Ensuring precise movement in sterile environments

- Warehousing & Logistics: Pallet transport, order fulfillment, and storage automation

AGVs vs. Traditional Material Handling Equipment

AGVs outperform manual forklifts and conveyors by offering:

- Predictable, programmable routing

- Lower long-term operating costs

- Safer interaction with workers

- Real-time performance data

- Seamless automation integration

For facilities aiming to modernize, AGVs offer clear long-term advantages.

Why Industrial AGV Solutions Are the Future

As manufacturing shifts toward smart, interconnected systems, Industrial AGV solutions serve as a foundational element of automated intralogistics. They support lean manufacturing principles, enhance productivity, improve safety, and enable end-to-end digital control of material movement.

With the ongoing rise of Industry 4.0 and smart factories, AGVs will be essential for maintaining competitiveness and operational resilience.