Heavy Duty Trackless Transfer Vehicle: Flexible Solutions for Industrial Material Handling

In heavy industrial environments where load capacity, safety, and flexibility are critical, heavy duty trackless transfer vehicles have become an essential material handling solution. Unlike rail-guided systems, trackless transfer vehicles operate without fixed tracks, allowing free movement across factory floors and complex production areas.

This article explains what heavy duty trackless transfer vehicles are, how they work, their key advantages, real-world applications, and important considerations for industrial deployment.

What Is a Heavy Duty Trackless Transfer Vehicle?

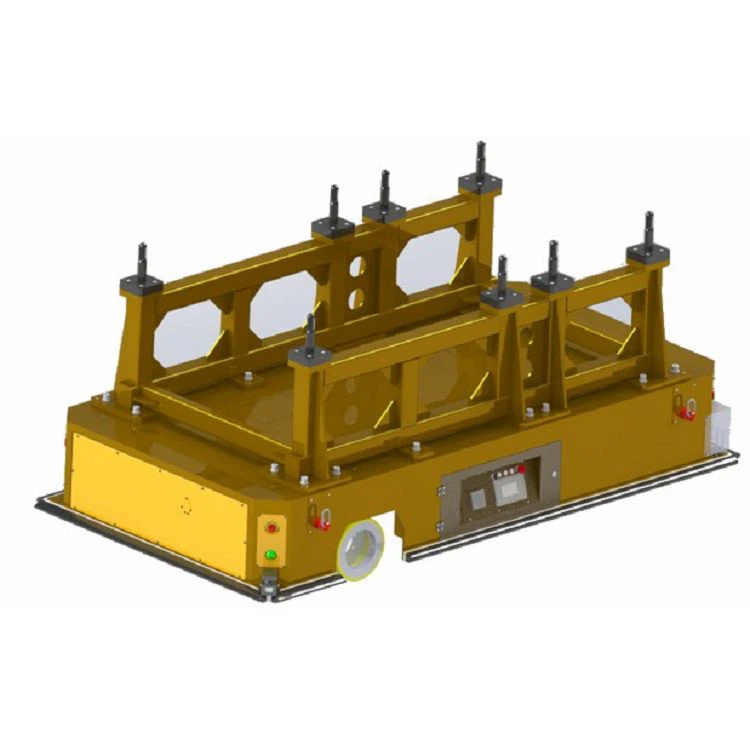

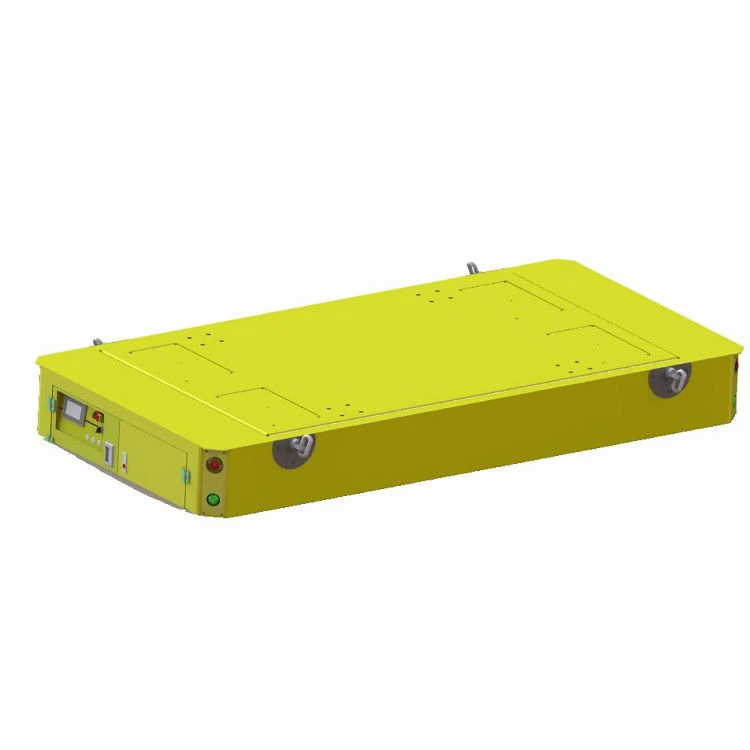

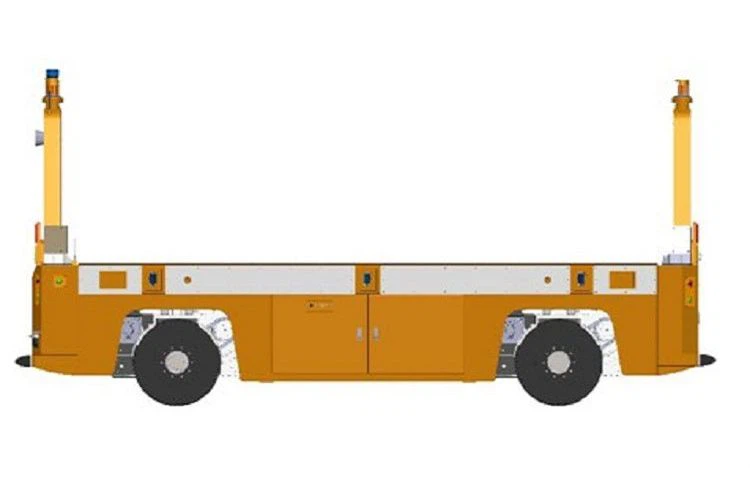

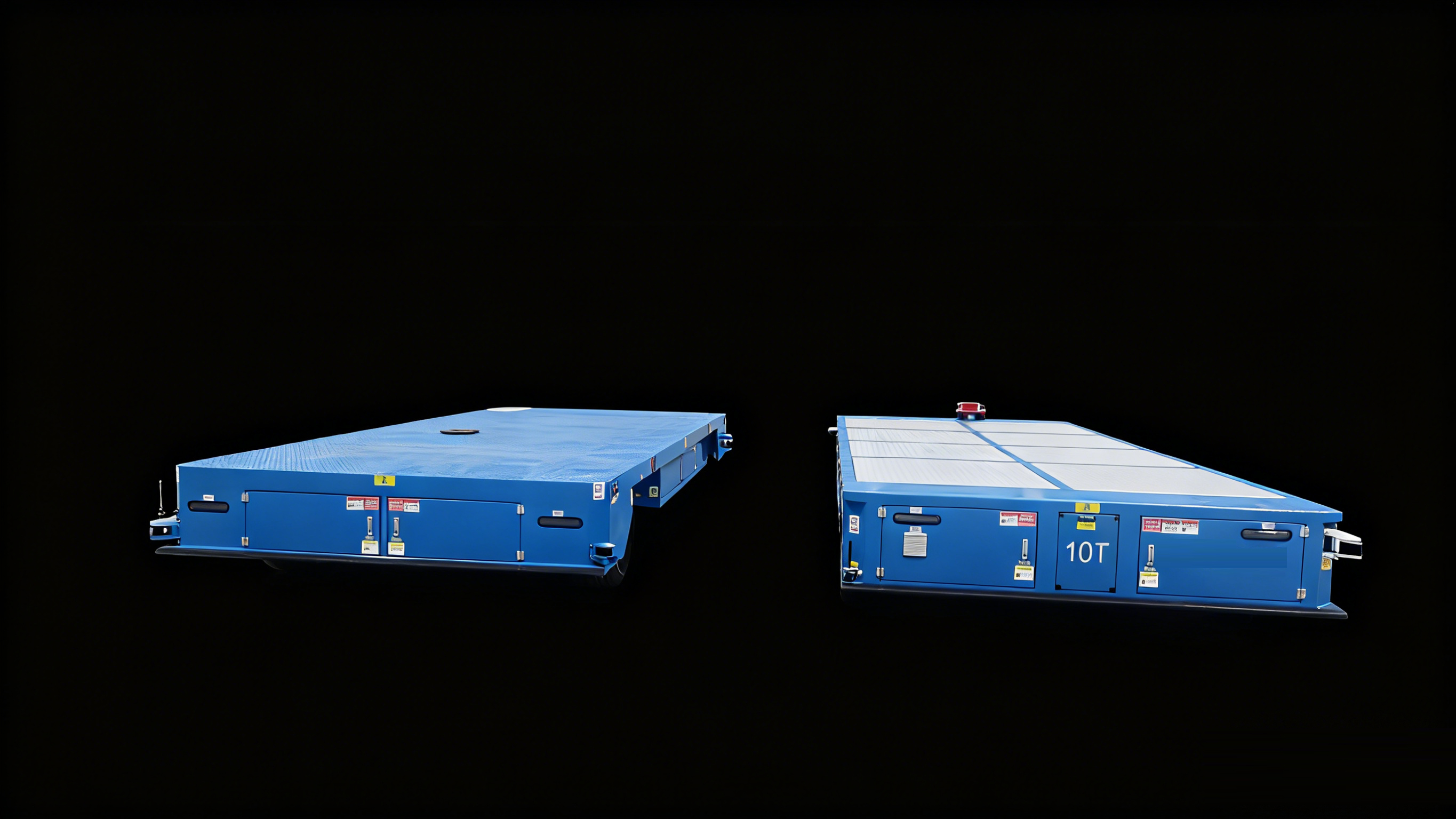

A heavy duty trackless transfer vehicle is a self-propelled industrial transport platform designed to carry extremely heavy loads without the need for rails or embedded guidance systems. These vehicles typically use rubber wheels or polyurethane wheels and are powered by electric drive systems.

Navigation can be:

- Manual (operator-controlled)

- Semi-automated

- Fully automated (AGV-based or guided by sensors)

Their trackless design offers greater operational flexibility compared to traditional rail transfer carts.

Key Features and Technical Advantages

1. High Load Capacity

Heavy duty trackless transfer vehicles can handle loads from several tons up to hundreds of tons, making them suitable for demanding industrial tasks.

2. Trackless and Flexible Operation

Without fixed rails, these vehicles can operate across large factory floors, change routes easily, and adapt to layout changes.

3. Electric Power System

Electric drive and battery systems provide clean, energy-efficient operation with low maintenance requirements.

4. Precise Steering and Control

Advanced steering mechanisms allow straight movement, turning, and precise positioning, even in confined spaces.

Common Industrial Applications

Manufacturing and Assembly Plants

Trackless transfer vehicles are used to move heavy molds, dies, machinery, and large components between workstations.

Steel, Shipbuilding, and Heavy Equipment

In heavy industries, these vehicles transport oversized steel structures, ship components, and heavy machinery safely and efficiently.

Warehousing and Logistics

For oversized or non-standard loads, trackless vehicles provide a safer alternative to forklifts and cranes.

Trackless Transfer Vehicle vs Rail-Guided Transfer Cart

| Feature | Trackless Transfer Vehicle | Rail Transfer Cart |

|---|---|---|

| Route flexibility | High | Fixed |

| Infrastructure | No rails required | Rails required |

| Deployment speed | Fast | Slower |

| Load capacity | Very high | Very high |

| Layout adaptability | Excellent | Limited |

Automation and System Integration

Modern heavy duty trackless transfer vehicles can be equipped with:

- PLC or AGV control systems

- Obstacle detection and safety sensors

- Wireless communication modules

- Integration with WMS, MES, or ERP systems

This allows seamless coordination with existing production and logistics workflows.

Safety and Reliability Considerations

- Emergency stop buttons

- Anti-collision sensors

- Speed control systems

- Load stability monitoring

Robust safety design is essential when transporting heavy loads in shared industrial environments.

Key Factors to Consider When Selecting a Trackless Transfer Vehicle

- Load weight and dimensions

- Floor conditions and gradients

- Turning radius and steering type

- Battery capacity and charging method

- Required level of automation

Custom engineering ensures the vehicle matches specific operational requirements.