Automated Guided Vehicles (AGVs) Examples: Types, Applications, and Benefits in 2026

In the fast-evolving world of industrial automation, Automated Guided Vehicles (AGVs) have become essential for efficient material handling. These driverless vehicles use advanced navigation to transport goods safely and reliably in warehouses, factories, and logistics centers. This article explores common AGV types, practical examples, and key benefits to help you understand “automated guided vehicles AGVs examples” in 2026.

What Are Automated Guided Vehicles (AGVs)?

AGVs are autonomous mobile robots that follow predefined paths or use smart navigation systems like lasers, magnets, or vision technology. They operate 24/7, reduce manual labor, and minimize errors. In 2026, AGVs play a vital role in modern warehouses and production lines, supporting higher productivity and safer operations.

Common Types of AGVs with Examples

AGVs come in various designs to suit different tasks. Here are the most popular types in use today:

1. Forklift AGVs

These vehicles automatically lift and move pallets, ideal for stacking in high-rack storage areas.

- Example: Transporting pallets from receiving to storage zones in large warehouses.

2. Tugger AGVs

Tugger AGVs pull multiple carts, making them perfect for delivering materials along assembly lines.

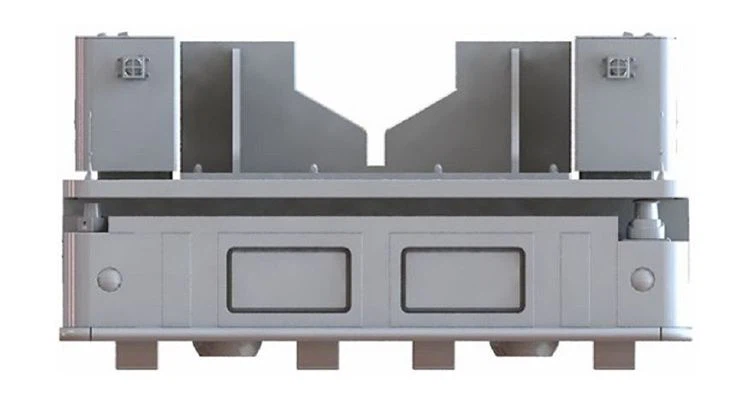

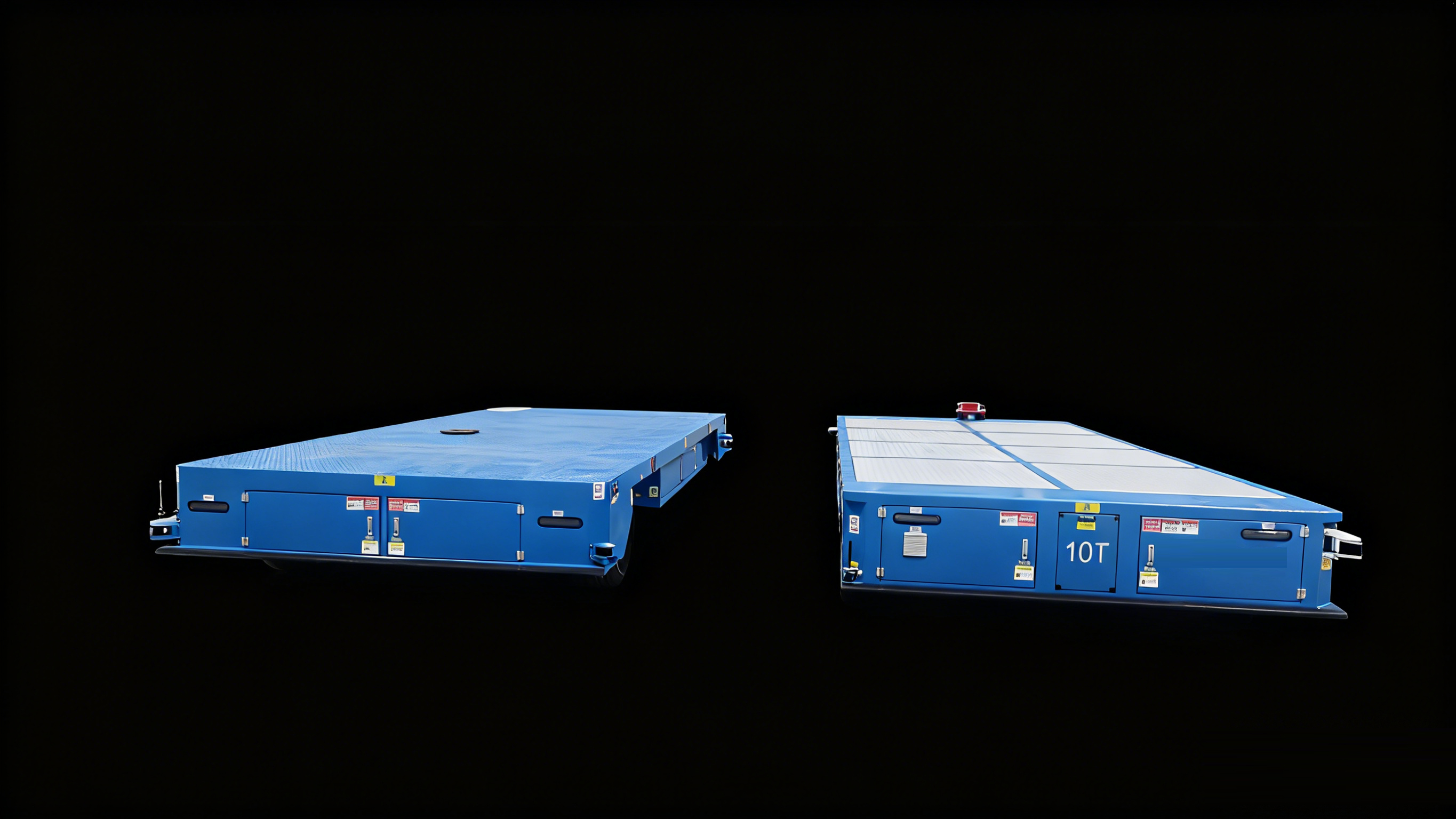

3. Unit Load AGVs

Designed to carry single heavy items like boxes or containers directly on their platform.

- Example: Moving finished goods between production and shipping areas.

Other types include cart-style AGVs for lighter loads and heavy-duty models for outdoor or extreme environments.

Real-World AGV Applications

AGVs are widely used across industries for seamless material flow:

- Warehousing and Logistics: Automatically moving goods from storage to picking or shipping zones.

- Manufacturing: Supplying parts to assembly lines for just-in-time production.

- Healthcare: Transporting supplies and meals within facilities for better efficiency.

- E-commerce Fulfillment: Handling high-volume order processing in distribution centers.

These applications show how AGVs improve speed, accuracy, and workspace safety.

Benefits and 2026 Trends

Adopting AGVs delivers clear advantages:

- Increased Efficiency: Boost productivity by 20-50% with continuous operation.

- Cost Savings: Lower labor costs and reduce damage from human error.

- Enhanced Safety: Built-in sensors prevent collisions.

- Scalability: Easy to expand fleets as needs grow.

In 2026, trends include improved AI navigation, hybrid systems with autonomous features, and greater integration with warehouse management software.

Contact YUNTONG (TIANJIN) INDUSTRIAL CO.,LTD today to explore how our AGVs can optimize your