Industry Coil Transfer Car: Efficient and Safe Solutions for Heavy Coil Handling

In steel processing and metal manufacturing industries, the safe and efficient handling of coils is a critical operational requirement. An industry coil transfer car is a specialized material handling solution designed to transport steel coils, aluminum coils, and other heavy rolled materials within industrial facilities.

This article explains how industry coil transfer cars work, their key features, typical applications, and important factors to consider when selecting the right system for industrial coil handling.

What Is an Industry Coil Transfer Car?

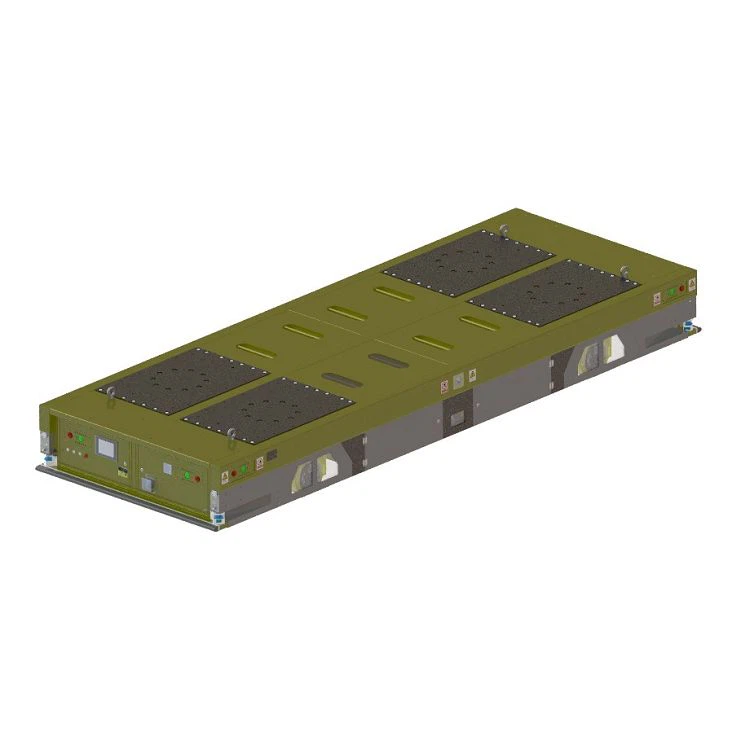

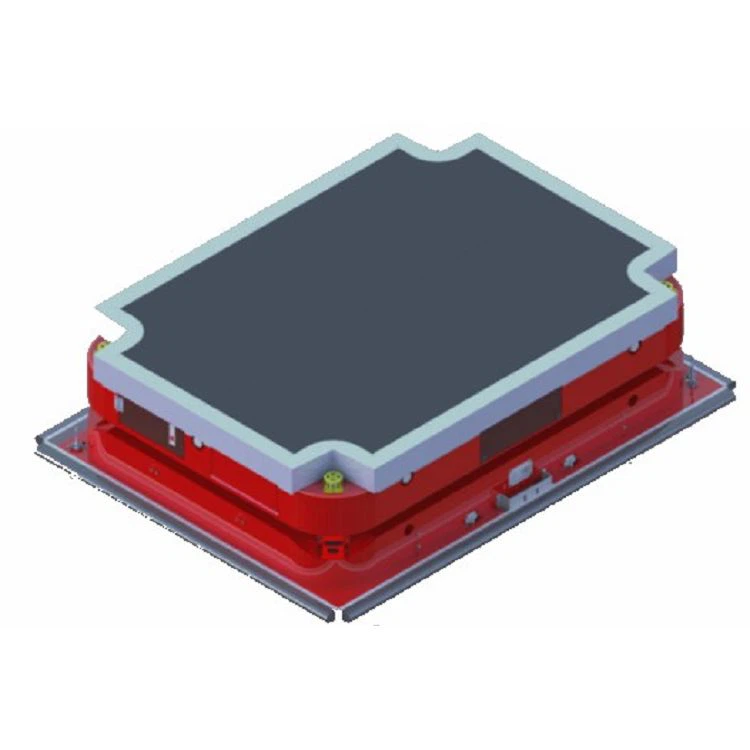

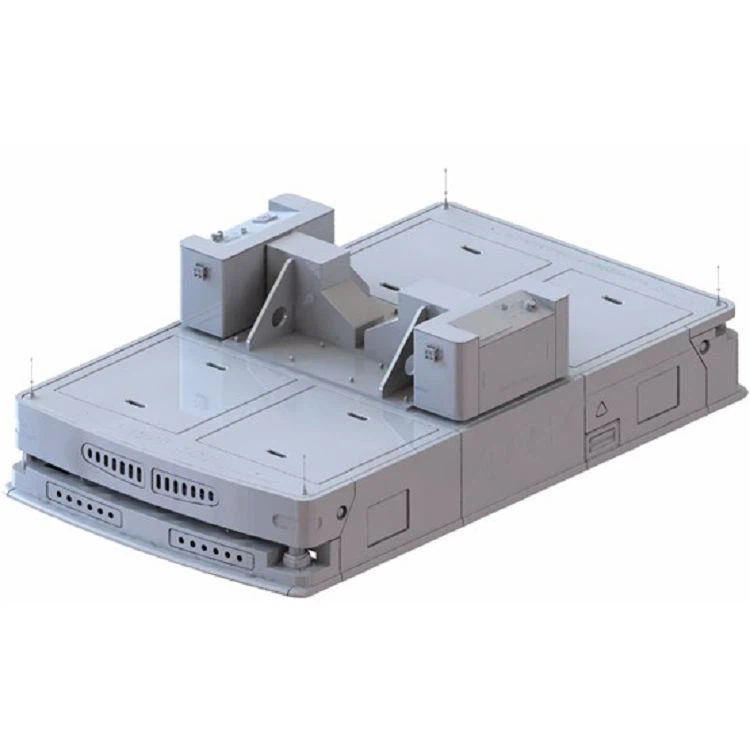

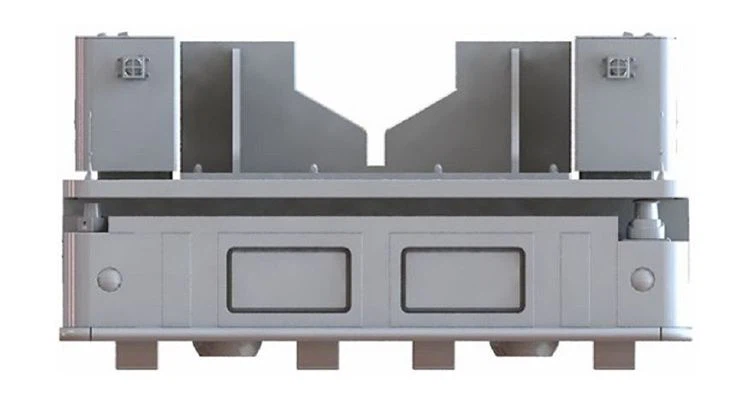

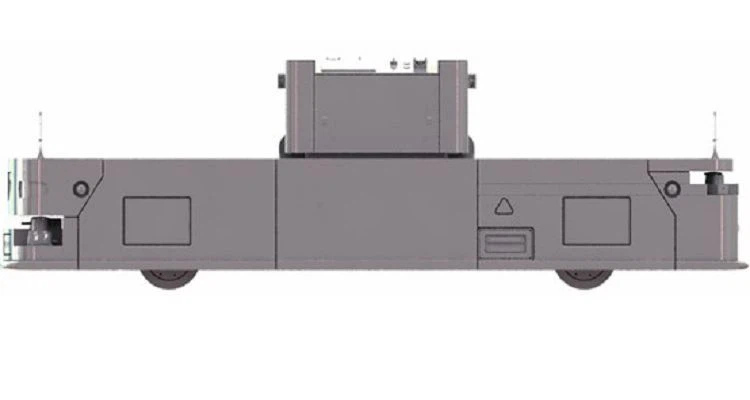

An industry coil transfer car is a heavy-duty transport vehicle designed specifically for moving cylindrical coil materials. These transfer cars are commonly equipped with V-shaped or saddle-type platforms to securely support coils during transportation.

They can operate as:

- Rail-guided transfer cars

- Trackless transfer vehicles

- Semi-automated or fully automated systems

Coil transfer cars are often customized based on coil size, weight, and production workflow.

Key Features and Technical Advantages

1. Secure Coil Positioning

V-shaped cradles or customized saddles prevent coil rolling and improve load stability during movement.

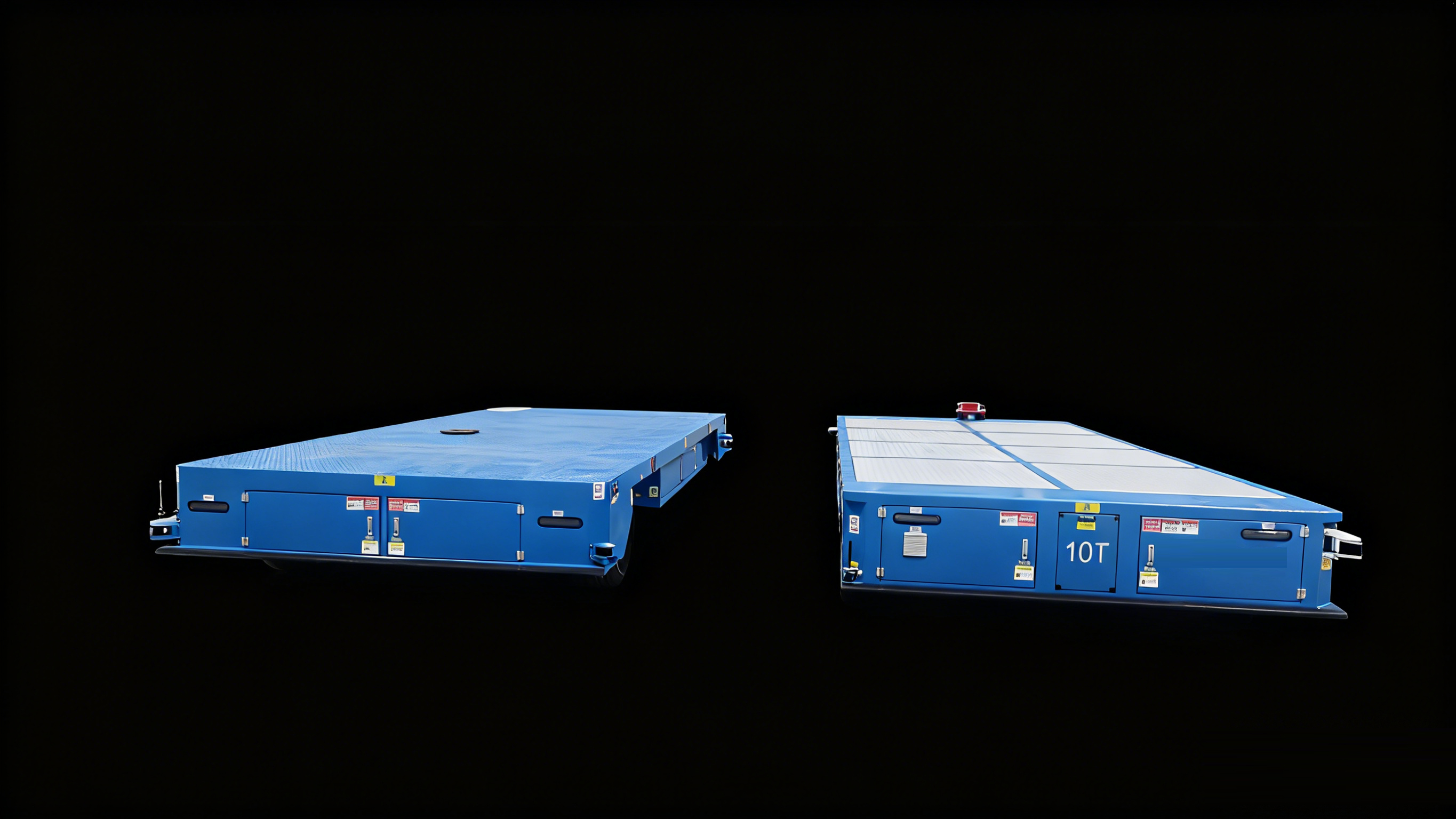

2. High Load Capacity

Industry coil transfer cars are capable of handling loads ranging from several tons to hundreds of tons, depending on design requirements.

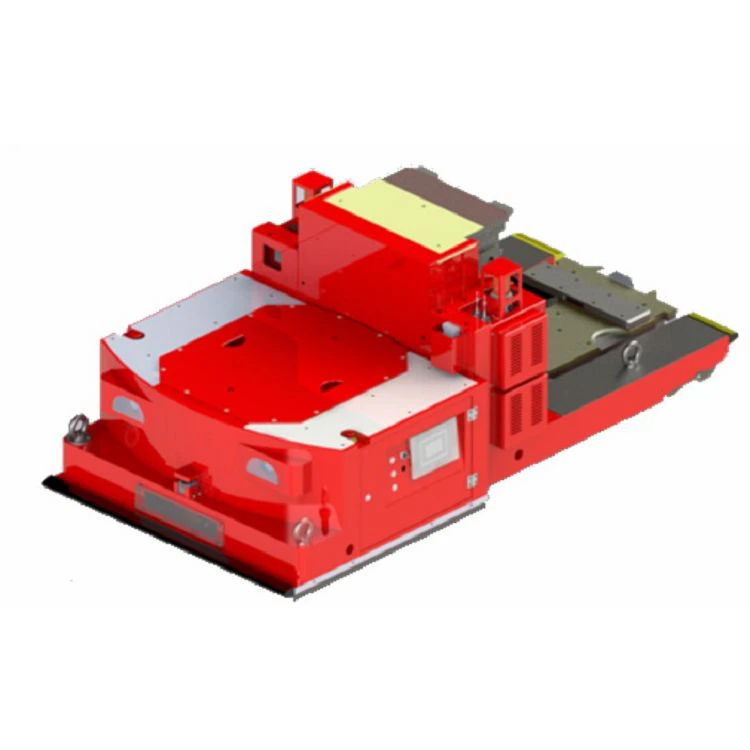

3. Electric Drive System

Electric-powered systems provide smooth acceleration, precise speed control, and energy-efficient operation.

4. Flexible Control Options

Manual, remote, or automated control systems allow integration with existing production lines and logistics systems.

Common Industrial Applications

Steel Mills and Coil Processing Lines

Coil transfer cars move hot-rolled and cold-rolled steel coils between slitting, pickling, and storage areas.

Aluminum and Copper Processing

These vehicles are widely used for transporting aluminum and copper coils in non-ferrous metal industries.

Manufacturing and Warehousing Facilities

In warehouses handling large coil inventories, transfer cars ensure safe and organized material flow.

Industry Coil Transfer Car vs Forklifts

| Aspect | Coil Transfer Car | Forklift |

|---|---|---|

| Load stability | Very high | Limited |

| Coil safety | Optimized | Risk of rolling |

| Load capacity | High to ultra-high | Limited |

| Operational safety | High | Moderate |

| Automation potential | High | Low |

Rail-Guided vs Trackless Coil Transfer Cars

| Feature | Rail-Guided | Trackless |

|---|---|---|

| Route | Fixed | Flexible |

| Installation | Requires rails | No rails |

| Layout adaptability | Low | High |

| Load capacity | Very high | High |

Automation and System Integration

Modern industry coil transfer cars can be integrated with:

- PLC control systems

- Manufacturing Execution Systems (MES)

- Warehouse Management Systems (WMS)

Automation improves handling efficiency, reduces manual intervention, and enhances safety.

Safety Considerations

- Anti-roll and anti-slip design

- Emergency stop systems

- Speed and braking control

- Load monitoring sensors

Proper safety design is essential when handling heavy and high-value coils.

Key Factors to Consider When Choosing a Coil Transfer Car

- Coil weight, diameter, and width

- Operating environment and floor conditions

- Required level of automation

- Power supply method

- Safety standards and compliance

Custom engineering ensures the transfer car meets specific operational needs.