Intelligent Trackless Navigation Automated Guided Vehicles: A Practical Guide for Modern Automation

As warehouse and factory automation continues to advance, intelligent trackless navigation automated guided vehicles (AGVs) are becoming an increasingly popular alternative to traditional guided systems. Unlike conventional AGVs that rely on fixed tracks or physical markers, trackless navigation AGVs use advanced sensing and localization technologies to move freely within dynamic environments.

This article explains how intelligent trackless navigation AGVs work, their key technologies, real-world applications, and what to consider when deploying them in modern industrial environments.

What Are Intelligent Trackless Navigation AGVs?

Intelligent trackless navigation automated guided vehicles are AGVs that operate without physical guidance infrastructure such as magnetic tape, QR codes, or inductive wires. Instead, they rely on software-based navigation and sensor fusion to understand their surroundings and navigate autonomously.

Key characteristics include:

- No physical tracks or floor modifications

- Software-defined routes

- Dynamic obstacle avoidance

- Higher adaptability to layout changes

These systems bridge the gap between traditional AGVs and fully autonomous mobile robots (AMRs).

Core Technologies Behind Trackless Navigation

1. LiDAR-Based Localization

LiDAR sensors scan the environment and generate real-time maps, enabling precise positioning even in large facilities.

2. SLAM (Simultaneous Localization and Mapping)

SLAM algorithms allow AGVs to build and update maps while operating, making them suitable for changing layouts.

3. Vision and Sensor Fusion

Cameras, IMUs, and ultrasonic sensors work together to enhance accuracy and safety in mixed human–robot environments.

4. Intelligent Motion Control

Advanced motion planning enables smooth navigation, adaptive speed control, and efficient route optimization.

Trackless Navigation vs Traditional AGVs

| Feature | Traditional AGVs | Trackless Navigation AGVs |

|---|---|---|

| Guidance method | Physical tracks | Software-based navigation |

| Layout flexibility | Low | High |

| Deployment speed | Slow | Fast |

| Infrastructure changes | Required | Minimal |

| Scalability | Limited | High |

Real-World Applications

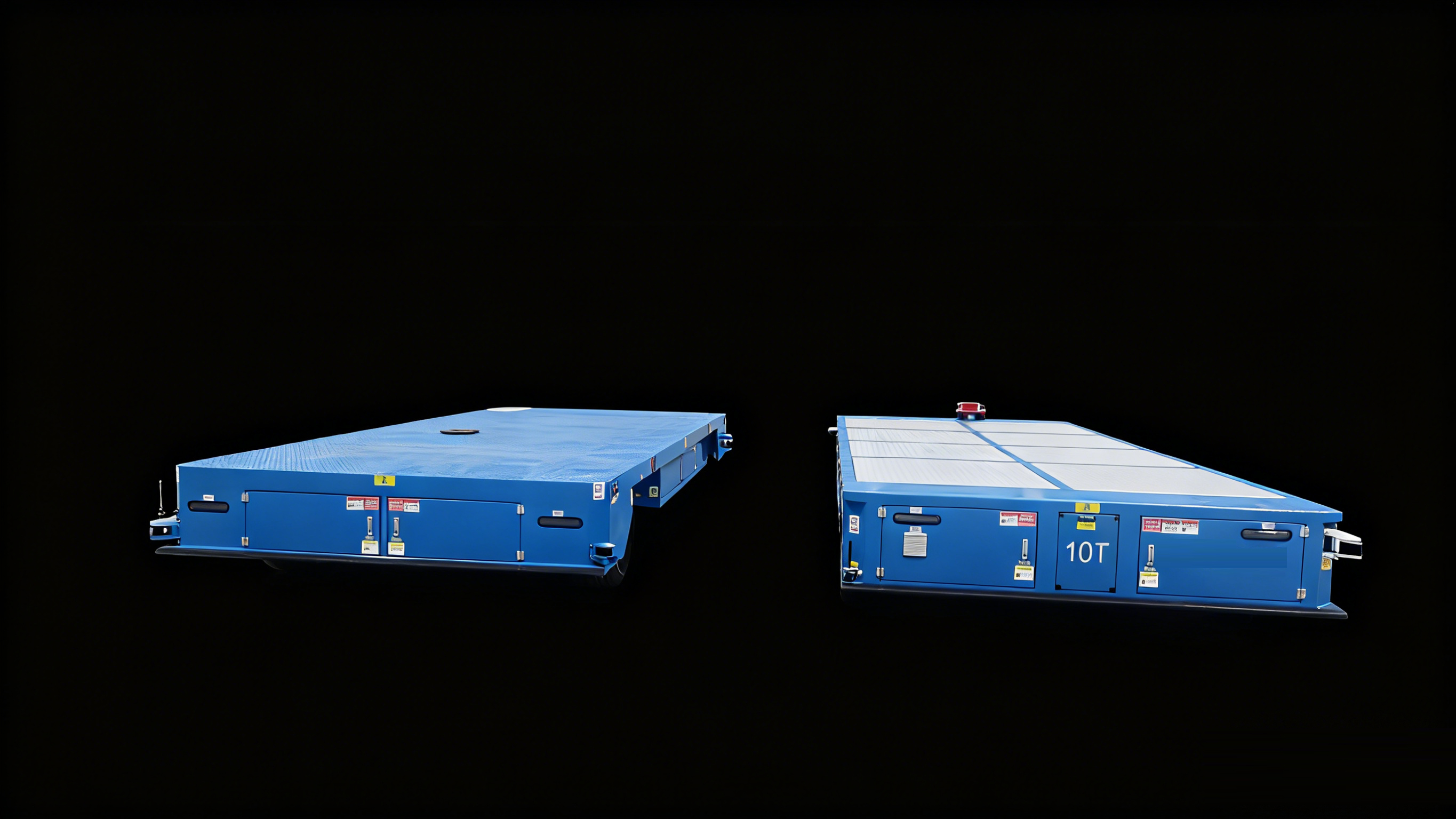

Warehouses and Distribution Centers

Trackless navigation AGVs are widely used for pallet transport, order fulfillment, and internal logistics where layout flexibility is critical.

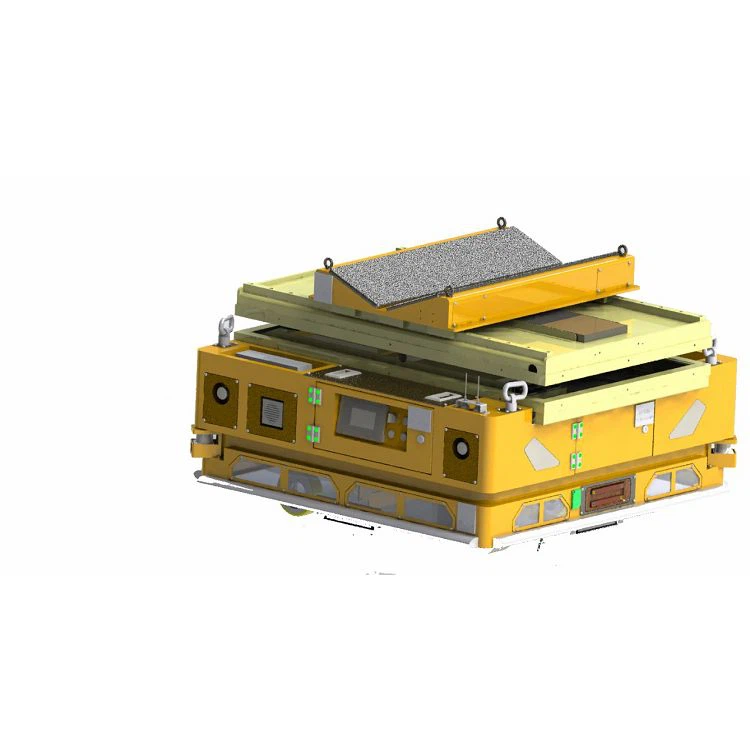

Manufacturing and Assembly Lines

In smart factories, these AGVs support line feeding, WIP transport, and just-in-time material delivery.

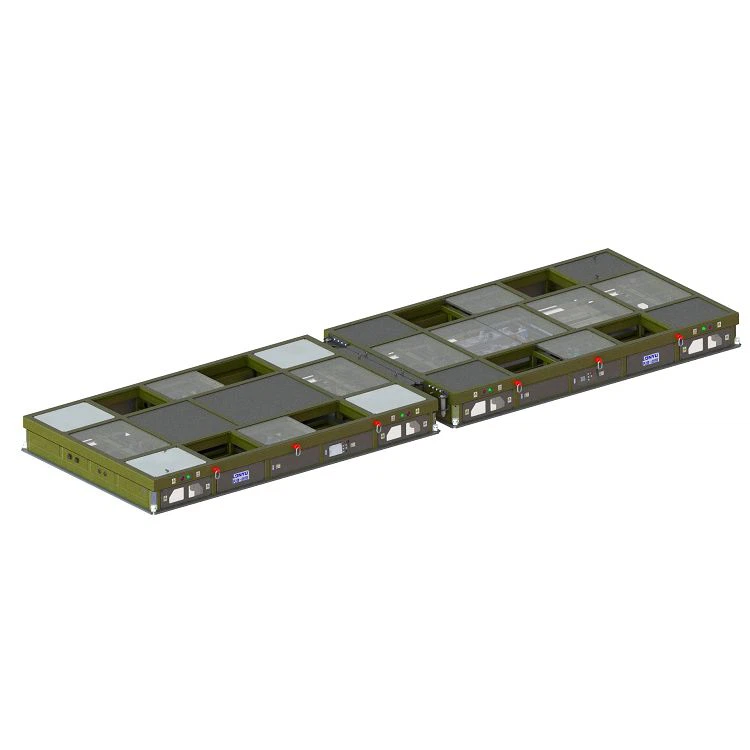

Outdoor and Semi-Outdoor Environments

Advanced trackless systems can operate in yards, loading zones, and inter-building logistics with appropriate environmental protection.

Key Benefits for Industrial Operations

- Faster deployment with minimal infrastructure changes

- Reduced downtime during system upgrades or layout adjustments

- Improved scalability as operational demand grows

- Lower long-term maintenance costs compared to physical guidance systems

These benefits make intelligent trackless navigation AGVs a strong choice for companies planning long-term automation.

Integration with WMS, ERP, and MES

Modern trackless navigation AGVs are designed to integrate seamlessly with warehouse and manufacturing systems. Standard communication protocols and APIs allow them to receive tasks, report status, and synchronize workflows with existing software platforms.

Successful integration depends on:

- Clear task logic and data flow design

- Stable network infrastructure

- Well-defined exception handling

Deployment Considerations and Best Practices

- Conduct site surveys and environmental testing

- Start with pilot zones before full-scale rollout

- Train operators and maintenance teams

- Monitor performance and continuously optimize routes