Warehouse AGV Supplier: Choosing the Right Partner for Smart Warehouse Automation

As warehouse automation accelerates worldwide, selecting a reliable warehouse AGV supplier has become a critical decision for logistics and distribution companies. Automated Guided Vehicles (AGVs) play a key role in improving efficiency, safety, and scalability in modern warehouses. A professional AGV supplier not only provides equipment but also delivers complete automation solutions tailored to specific operational needs.

What Does a Warehouse AGV Supplier Provide?

A warehouse AGV supplier offers more than just automated vehicles. Comprehensive services typically include system design, AGV manufacturing, software integration, installation, and after-sales support. By analyzing warehouse layouts and workflow requirements, suppliers develop customized AGV solutions that optimize material flow and maximize productivity.

Types of Warehouse AGVs Offered by Suppliers

A qualified warehouse AGV supplier usually provides a wide range of AGV models to meet different warehouse applications:

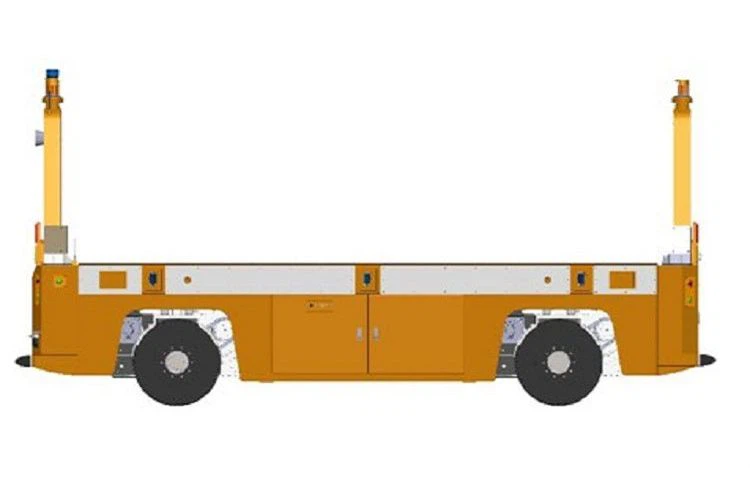

Pallet AGVs

Designed for transporting pallets between receiving, storage, and shipping areas.

AGV Forklifts

Automate lifting, stacking, and high-rack storage operations.

Tugger AGVs

Ideal for pulling multiple carts in batch transportation scenarios.

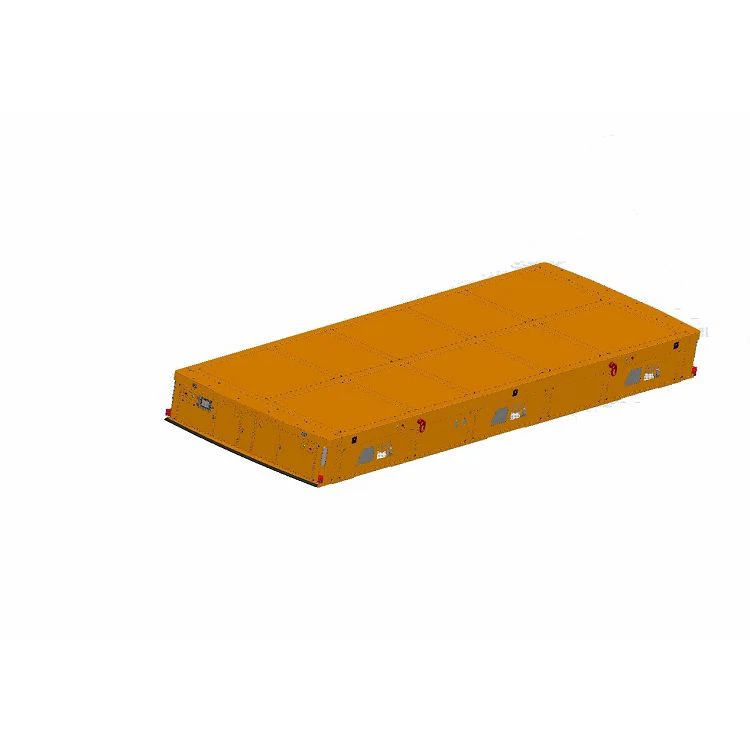

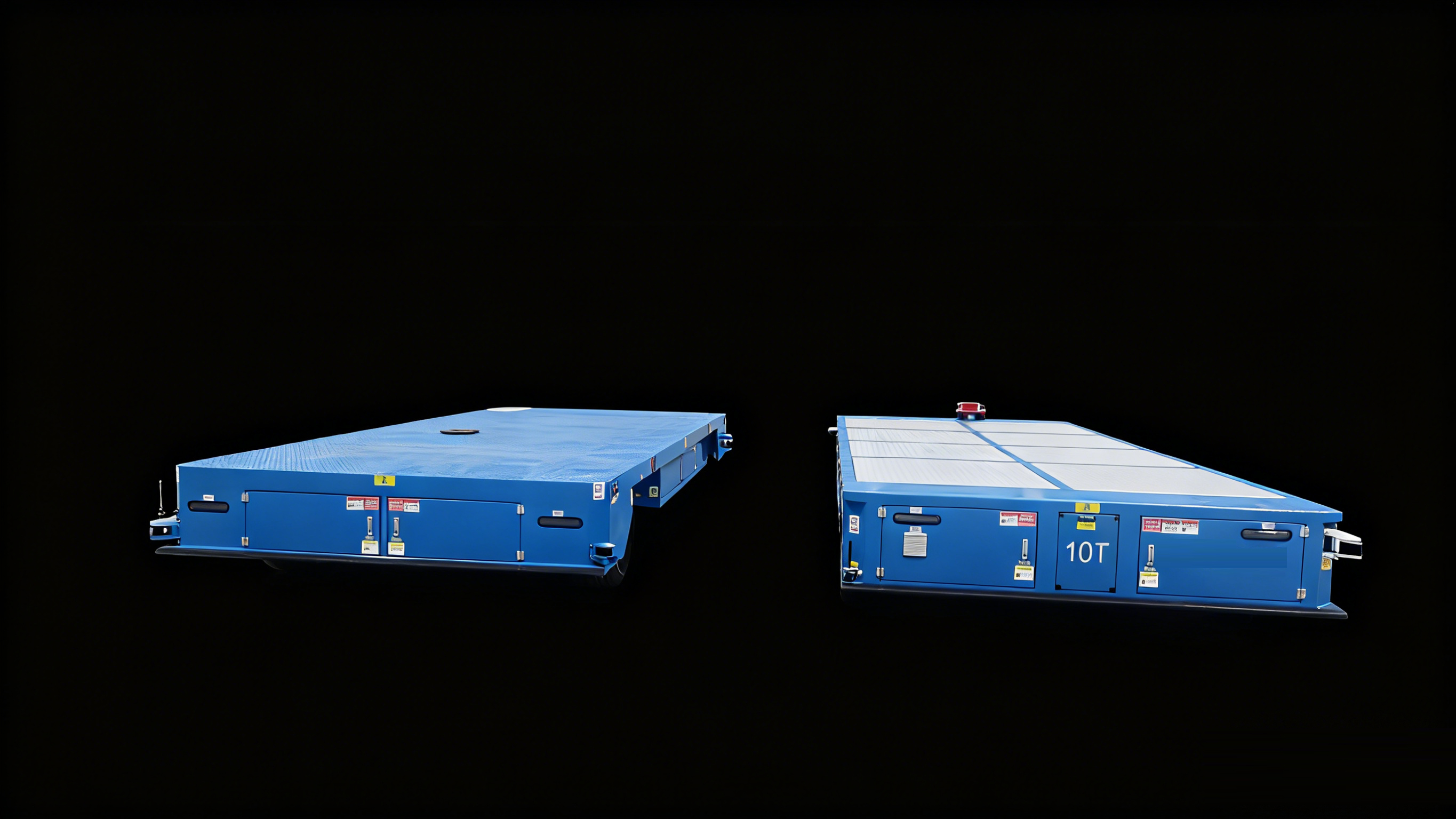

Unit Load AGVs

Use conveyors or lift platforms to move cartons, totes, and containers.

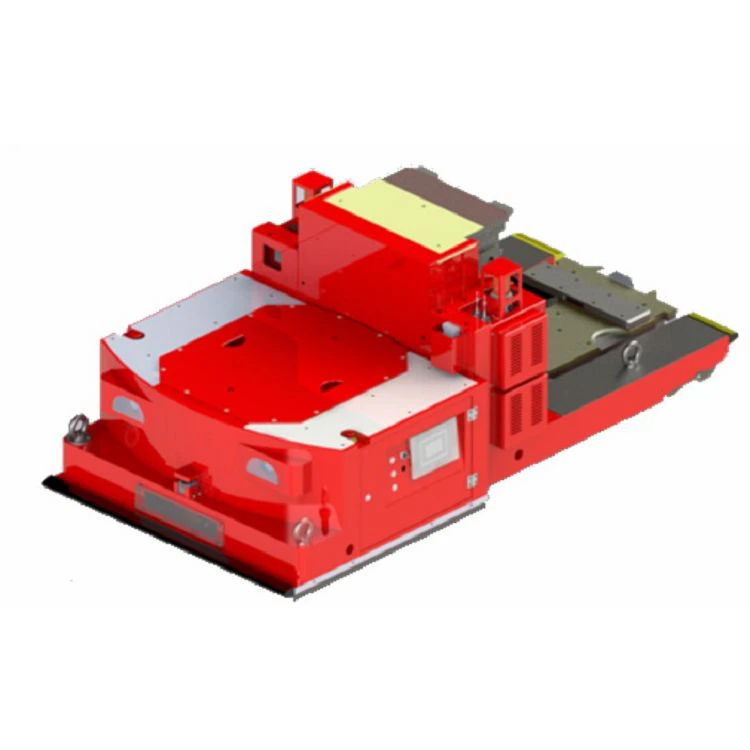

Customized AGVs

Tailored solutions for narrow aisles, heavy loads, or special warehouse layouts.

Key Advantages of Working With a Professional Warehouse AGV Supplier

Choosing an experienced warehouse AGV supplier delivers multiple benefits:

Customized Automation Solutions

Suppliers design AGV systems based on real warehouse conditions, ensuring optimal performance.

Advanced Navigation Technology

Modern AGV suppliers offer solutions using magnetic guidance, laser navigation, QR codes, or intelligent trackless SLAM navigation.

Seamless System Integration

AGVs are integrated with WMS, ERP, and other warehouse management platforms for real-time control.

Reliable Safety Standards

Professional suppliers ensure AGVs comply with international safety regulations and operate safely alongside workers.

Long-Term Technical Support

Ongoing maintenance, upgrades, and technical assistance ensure stable system operation.

Industries Served by Warehouse AGV Suppliers

Warehouse AGV suppliers support automation across multiple industries:

- E-commerce and Retail Warehousing

- Third-Party Logistics (3PL)

- Manufacturing Warehouses

- Automotive Parts Distribution

- Food, Beverage, and Pharmaceutical Storage

How to Choose the Right Warehouse AGV Supplier

When selecting a warehouse AGV supplier, consider the following factors:

- Experience in warehouse automation projects

- Range of AGV products and customization capability

- Software and system integration expertise

- Safety certifications and quality standards

- After-sales service and global support network

A supplier with proven industry experience and strong technical capabilities ensures successful long-term automation.

Warehouse AGV Supplier vs. Traditional Equipment Providers

Unlike traditional material handling equipment suppliers, AGV suppliers deliver intelligent, data-driven solutions. AGVs provide flexible routing, automated scheduling, and real-time monitoring, offering higher efficiency and lower long-term operational costs compared to manual forklifts or conveyor systems.

Why Warehouse AGV Suppliers Are Essential for Smart Warehouses

In the era of Industry 4.0, warehouse AGV suppliers play a vital role in building smart logistics systems. Their solutions enable real-time inventory movement, intelligent scheduling, and scalable automation, helping warehouses stay competitive in fast-changing markets.