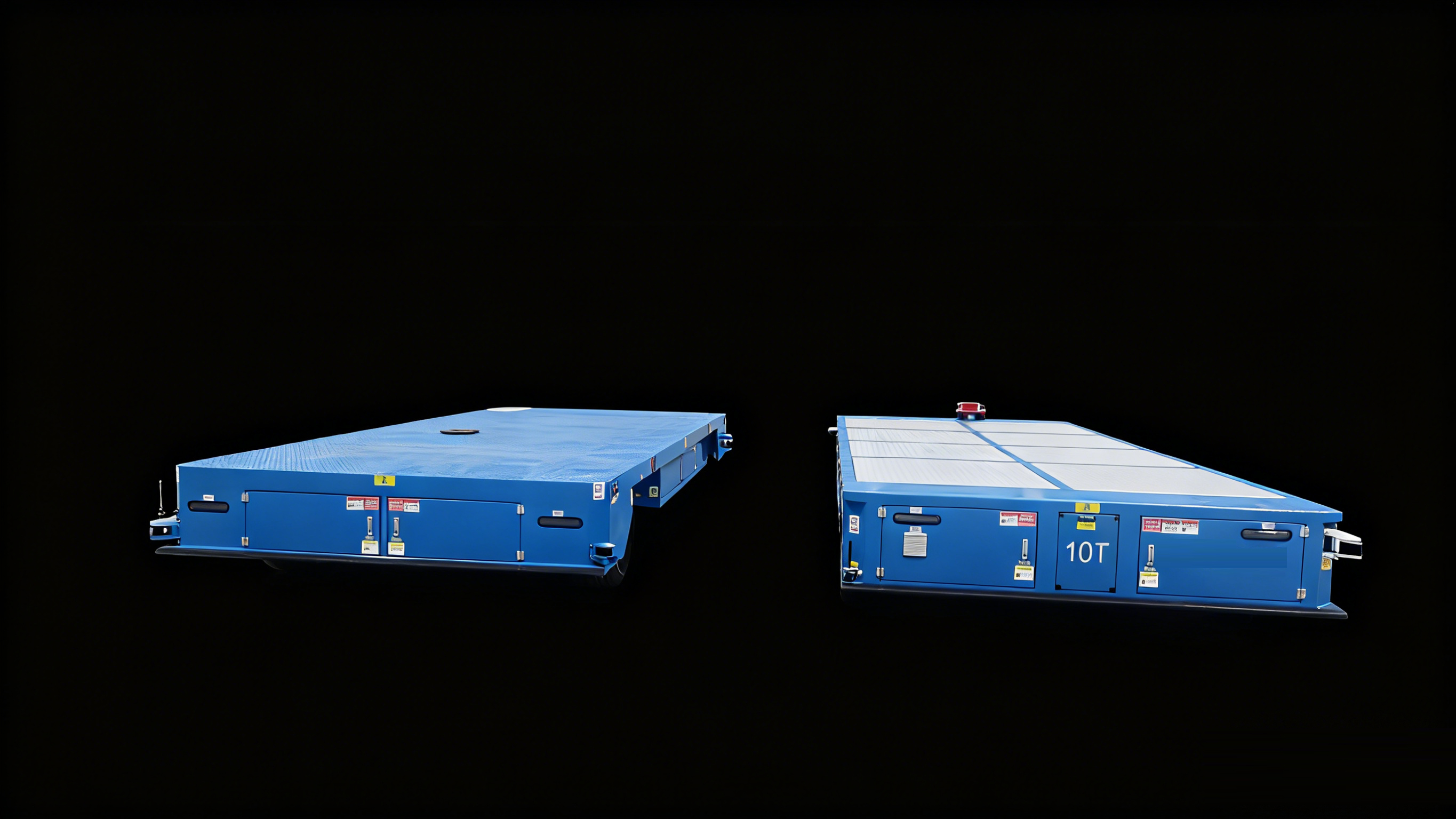

Intelligent Trackless Navigation Automated Guided Vehicles: The Future of Flexible Automation

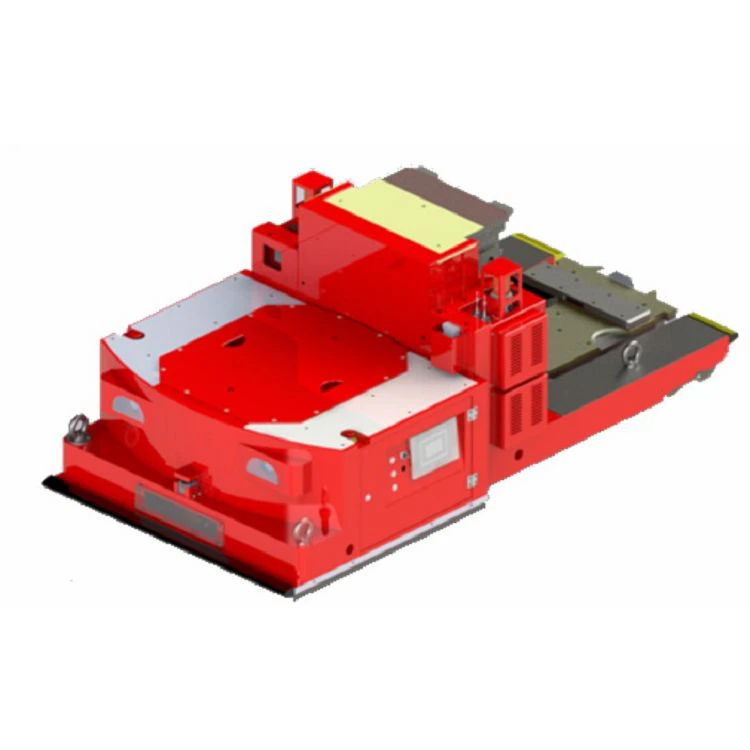

As industrial automation continues to evolve, intelligent trackless navigation automated guided vehicles are rapidly gaining attention. Unlike traditional AGVs that rely on fixed tracks or magnetic tape, trackless navigation AGVs use advanced sensors and intelligent algorithms to move freely within industrial environments. This flexibility makes them ideal for modern factories and warehouses seeking efficient, scalable, and smart material handling solutions.

What Are Intelligent Trackless Navigation Automated Guided Vehicles?

Intelligent trackless navigation automated guided vehicles are autonomous transport systems that do not require physical tracks, wires, or floor markings. They rely on technologies such as SLAM (Simultaneous Localization and Mapping), LiDAR, vision systems, and AI-based navigation to understand their surroundings and move safely.

These AGVs can dynamically adjust routes, avoid obstacles, and operate efficiently in changing environments, making them a key component of next-generation automation.

How Trackless Navigation AGVs Work

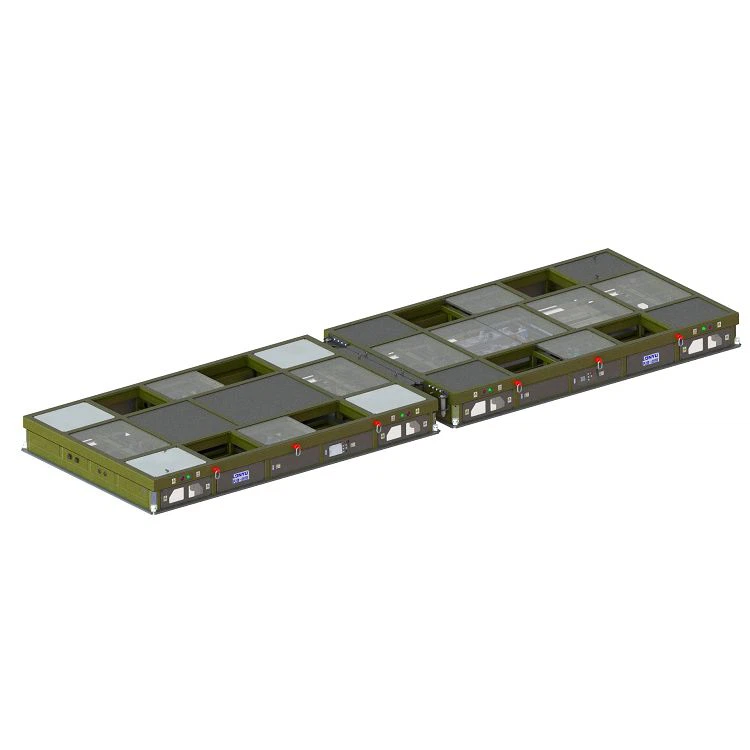

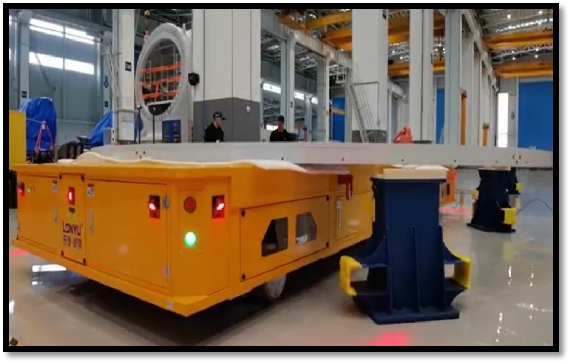

Trackless navigation AGVs continuously scan their environment using LiDAR sensors, cameras, and inertial measurement units. By identifying natural features such as walls, shelves, and columns, they build digital maps and localize themselves in real time.

A central fleet management system assigns tasks, optimizes routes, and coordinates multiple vehicles, ensuring smooth traffic flow and efficient material transport without the need for fixed infrastructure.

Key Technologies Behind Intelligent Trackless AGVs

Several advanced technologies enable trackless navigation AGVs to operate intelligently:

SLAM Navigation

Allows AGVs to map the environment and determine their position without external markers.

LiDAR and Vision Sensors

Provide accurate distance measurement, obstacle detection, and environment recognition.

AI-Based Path Planning

Optimizes routes in real time, adapting to changes in layout or traffic.

Wireless Communication

Enables real-time coordination with warehouse management and production systems.

Advantages of Intelligent Trackless Navigation AGVs

Trackless navigation AGVs offer significant advantages over traditional guided vehicles:

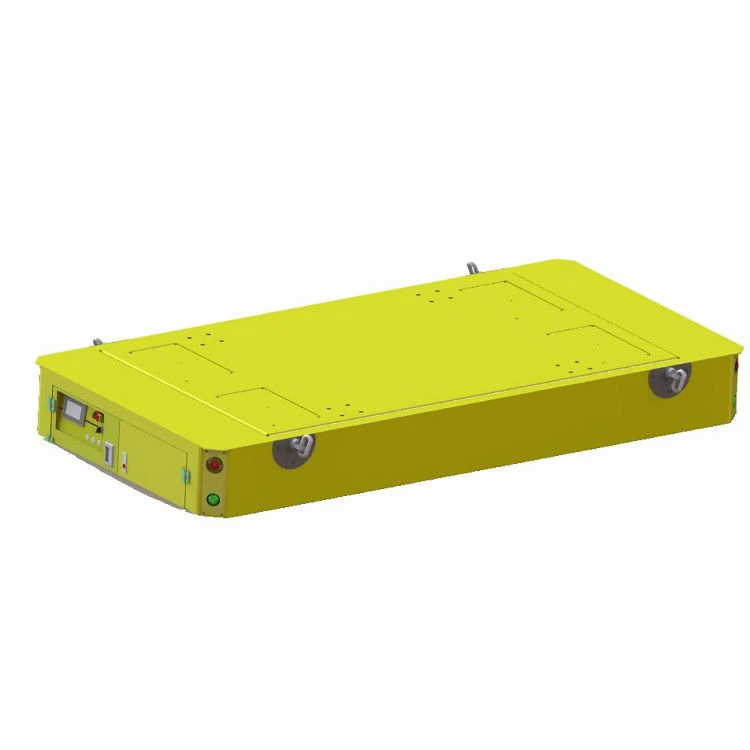

High Flexibility

No physical tracks or tapes are required, making layout changes quick and cost-effective.

Lower Infrastructure Costs

Eliminates the need for floor modifications and maintenance of guidance paths.

Improved Safety

Advanced sensors allow safe operation alongside human workers.

Scalability

AGV fleets can be expanded or reconfigured easily as operational needs grow.

Smart Integration

Seamlessly integrates with WMS, MES, and ERP systems for intelligent automation.

Applications in Modern Industry

Intelligent trackless navigation automated guided vehicles are widely used in various industries:

- Warehousing and Logistics: Pallet transport, order fulfillment, and cross-docking

- Manufacturing: Line feeding, work-in-progress transportation

- Automotive: Component and assembly movement

- Electronics: Precise handling of sensitive materials

- Food and Pharmaceuticals: Clean, hygienic, and controlled logistics environments

Trackless Navigation AGVs vs. Traditional AGVs

Traditional AGVs rely on fixed guidance methods, which limit flexibility and require infrastructure changes. Trackless navigation AGVs, on the other hand, adapt to dynamic environments and reduce downtime during layout adjustments. This makes them ideal for smart factories and fast-changing warehouse operations.

Why Trackless Navigation AGVs Are the Future

With the rise of Industry 4.0 and intelligent manufacturing, flexibility and data-driven automation are critical. Intelligent trackless navigation automated guided vehicles provide the adaptability, efficiency, and connectivity needed to support digital transformation and future-ready operations.