Automated Guided Vehicles in Warehouse: Improving Efficiency and Smart Logistics

Automated Guided Vehicles (AGVs) are becoming an essential technology in modern warehouse operations. As e-commerce growth and supply chain demands increase, warehouses must improve efficiency, accuracy, and safety. Automated guided vehicles in warehouse environments provide a reliable solution for automating internal material movement, reducing labor dependency, and supporting 24/7 logistics operations.

What Are Automated Guided Vehicles in Warehouse Operations?

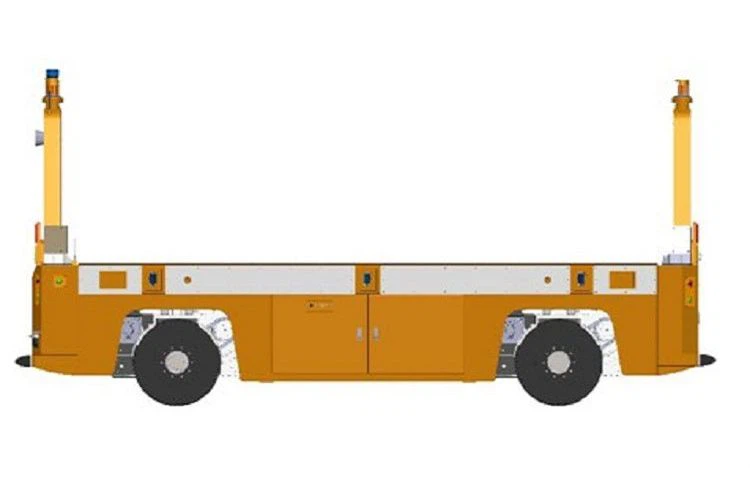

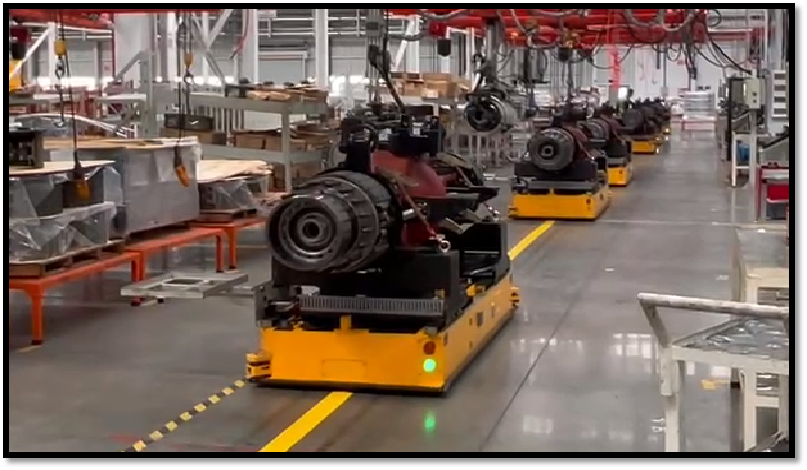

Automated guided vehicles in warehouse settings are driverless vehicles designed to transport pallets, cartons, containers, and goods between storage, picking, and shipping areas. AGVs follow predefined routes or intelligent navigation systems such as magnetic tape, laser guidance, QR codes, or SLAM navigation.

By replacing manual forklifts and pallet trucks, AGVs help warehouses maintain consistent material flow and reduce human error.

How Automated Guided Vehicles Work in Warehouses

AGVs operate through a combination of sensors, navigation systems, and fleet management software. A central control system assigns transport tasks, monitors vehicle positions, and optimizes traffic flow.

AGVs can automatically handle inbound goods, move inventory to storage locations, support order picking, and deliver finished orders to outbound docks. Safety scanners and obstacle detection systems ensure secure operation alongside human workers.

Types of Automated Guided Vehicles Used in Warehouses

Warehouses deploy different AGV types based on operational needs:

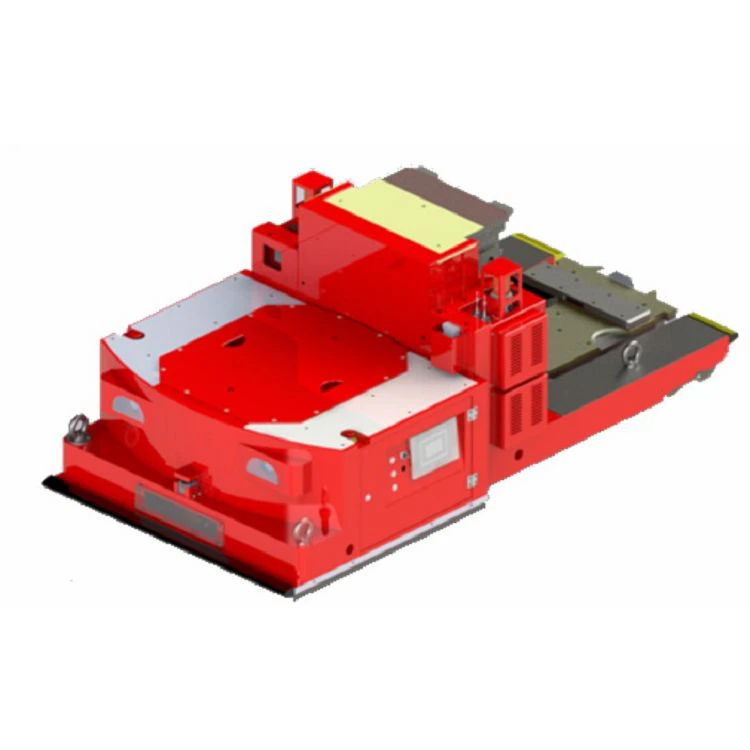

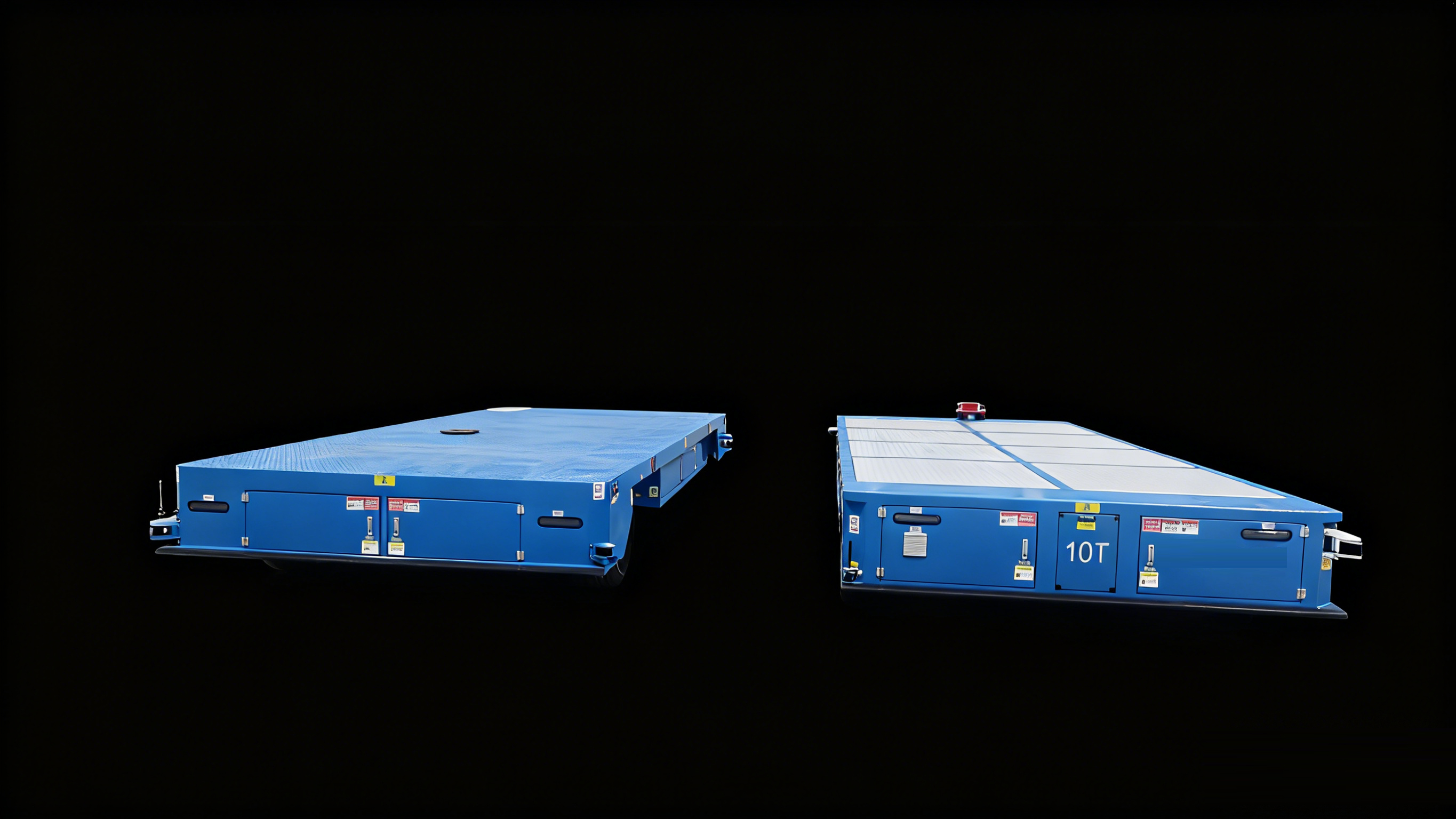

AGV Pallet Transporters

Designed for moving pallets between receiving, storage, and shipping areas.

AGV Forklifts

Automate lifting, stacking, and high-rack storage operations.

Tugger AGVs

Pull multiple carts to support batch transportation and replenishment.

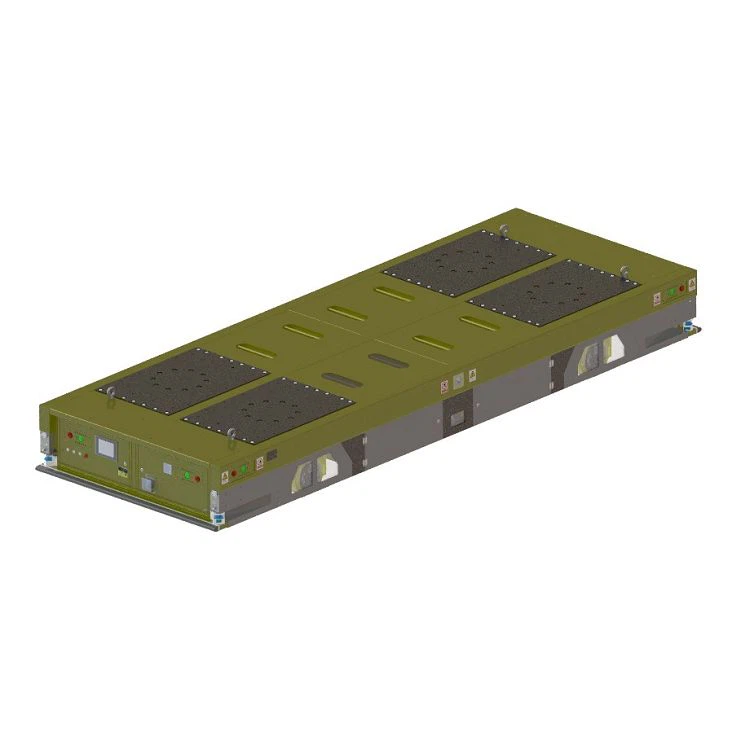

Unit Load AGVs

Use conveyors or lift platforms to transport cartons, totes, or containers.

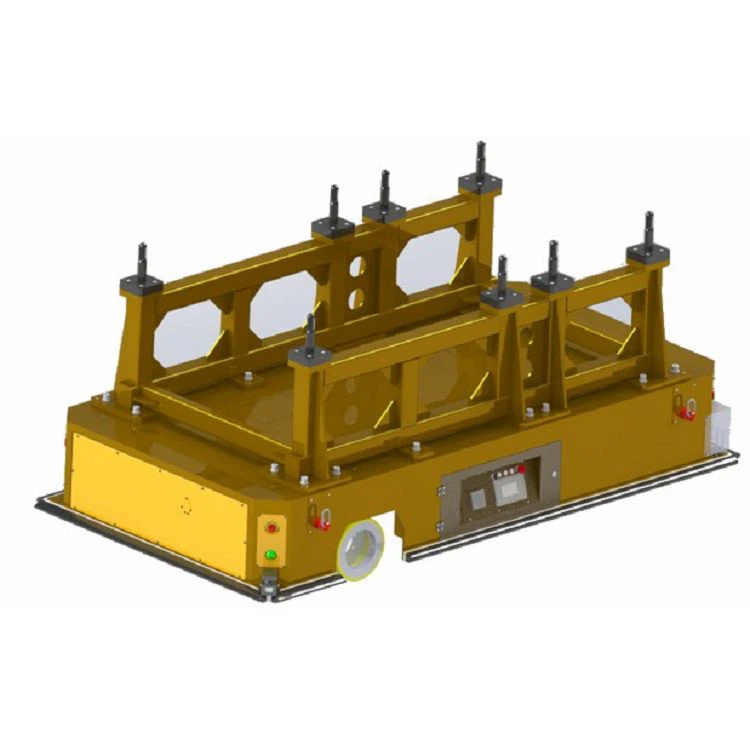

Customized Warehouse AGVs

Built for narrow aisles, high-density storage, or specialized warehouse layouts.

Key Benefits of Automated Guided Vehicles in Warehouse Automation

Increased Productivity

AGVs operate continuously without fatigue, improving throughput and reducing delays.

Improved Workplace Safety

Equipped with sensors, emergency stops, and collision-avoidance systems, AGVs reduce accidents and damage.

Lower Labor Costs

Automation reduces reliance on manual handling and minimizes labor shortages.

High Accuracy and Reliability

AGVs follow precise routes, ensuring consistent and error-free material transport.

Scalable Automation

Warehouse operators can expand AGV fleets as order volumes increase.

Applications of AGVs in Modern Warehouses

Automated guided vehicles in warehouse environments support a wide range of applications, including:

- Pallet movement and staging

- Order picking support

- Inventory replenishment

- Cross-docking operations

- Automated loading and unloading

AGVs vs. Traditional Warehouse Equipment

Compared with forklifts and conveyor systems, AGVs offer higher flexibility, improved safety, and lower long-term operating costs. They can adapt to layout changes with minimal infrastructure modifications and integrate easily with digital warehouse management systems.

Integration With Warehouse Management Systems

AGVs integrate seamlessly with WMS, ERP, and other digital platforms. This enables real-time inventory tracking, automated task assignment, and data-driven optimization. Such integration supports smart warehouse development and enhances overall operational visibility.

Why Automated Guided Vehicles Are the Future of Warehousing

As warehouses move toward Industry 4.0, AGVs serve as a foundation for intelligent logistics. Their ability to automate repetitive transport tasks, operate reliably, and scale with business growth makes them an indispensable solution for future-ready warehouses.

Conclusion

Automated guided vehicles in warehouse operations deliver significant improvements in efficiency, safety, and cost control. By automating material movement and integrating with smart management systems, AGVs help warehouses achieve higher productivity and operational stability. For businesses seeking competitive advantage in logistics, AGVs represent a proven and scalable automation solution.