Factory Automation AGV: The Core Engine Driving Smart Logistics

Meta Description: Discover how Automated Guided Vehicles (AGVs) are revolutionizing factory automation. Explore AGV types, key benefits, applications, and how to choose the right solution to boost efficiency and cut costs in your smart factory.

Introduction: Beyond Traditional Logistics, Welcome the Era of Flexible Manufacturing

In today’s hyper-competitive manufacturing landscape, the wave of factory automation has extended beyond assembly lines to the very flow of materials. Traditional fixed conveyors and manual forklifts are being replaced by flexible, intelligent Automated Guided Vehicles (AGVs). More than just transporters, AGVs are the “intelligent lifeline” connecting production, warehousing, and distribution—the foundational element for building Flexible Manufacturing Systems (FMS) and Smart Factories. This article dives deep into how AGVs have become the core driving force of factory automation.

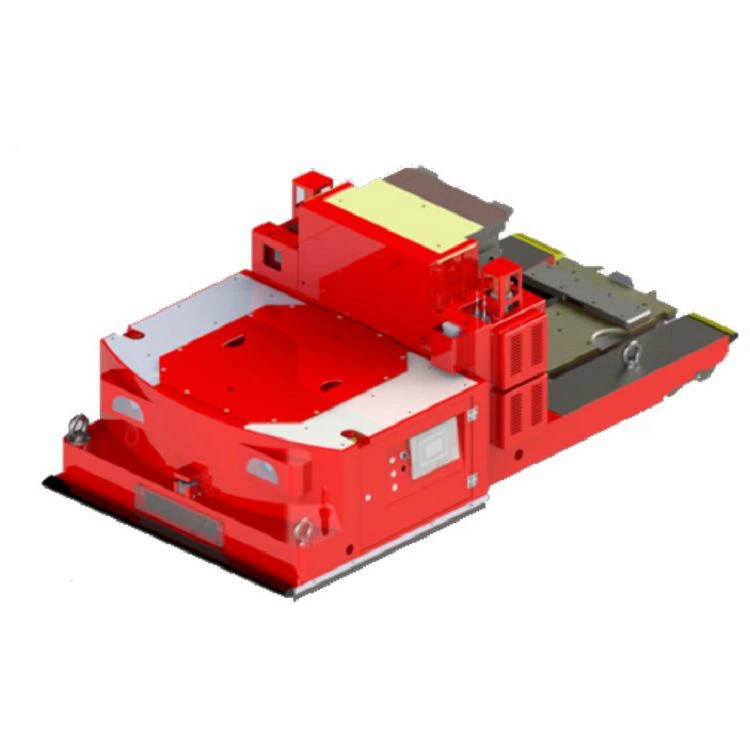

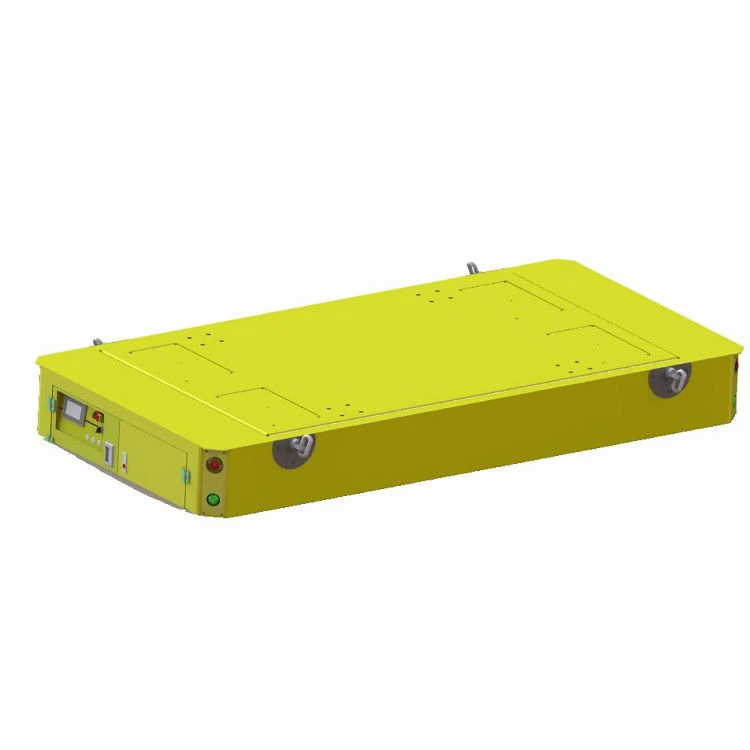

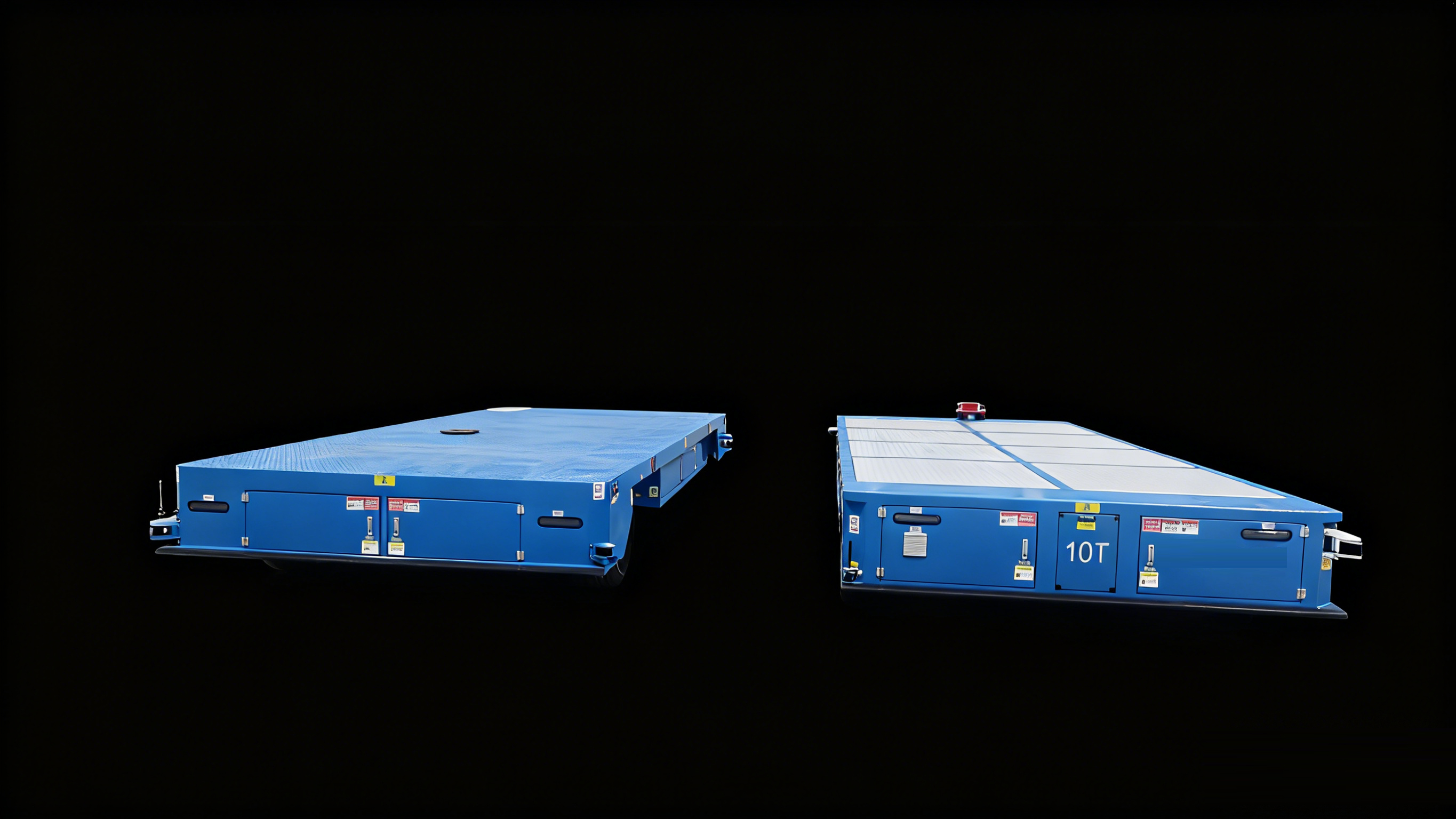

What is a Factory Automation AGV?

An Automated Guided Vehicle (AGV) is an unmanned, self-propelled vehicle equipped with automatic navigation systems like lasers, magnets, or vision cameras. It follows predefined paths or uses advanced SLAM (Simultaneous Localization and Mapping) technology for autonomous navigation. Operating without human intervention, it performs material, component, or finished goods handling tasks, seamlessly integrating with upper-level management systems (like MES or WMS) for real-time instruction and feedback.

Core Benefits of AGVs in Factory Automation

- 24/7 Uninterrupted Operation: AGVs don’t require breaks, significantly boosting equipment utilization and production throughput.

- Enhanced Safety: With multi-layer obstacle avoidance (lidar, sensors, safety bumpers), AGVs eliminate accidents caused by human fatigue or error, enabling safe human-robot collaboration.

- High Precision & Traceability: Pinpoint delivery to specific locations, combined with RFID or barcode scanning, enables full material traceability. This provides a data foundation for lean manufacturing and quality control.

- Superior Flexibility & Scalability: Paths can be modified via software. When reconfiguring or expanding production lines, AGV systems adapt quickly, offering a high return on investment (ROI).

- Reduced Long-Term Operational Costs: AGVs decrease reliance on manual forklift operators and fixed conveyor systems, optimizing workforce allocation.

Breaking Down Main Navigation Technologies

- Laser Navigation: Uses reflective targets installed in the environment for high-precision positioning. Offers flexible path planning and is an industry standard.

- SLAM Natural Navigation: Requires no infrastructure changes. Vehicles use onboard sensors to map and locate themselves in real-time. Offers the highest flexibility and is the leading trend for future systems.

- Magnetic/Inductive Guidance: Follows magnetic tape or wires embedded in the floor. Provides a simple, reliable, and cost-effective solution for fixed, repetitive routes.

- Vision/QR Code Navigation: Cameras read visual markers or QR codes on the floor for localization. A balance of accuracy and low infrastructure cost, common in logistics.

Key Application Scenarios in the Factory

- Production Line Feeding: Automatically delivers components from the warehouse to assembly stations in sequence (SPS kit delivery), enabling Just-in-Time (JIT) production.

- Inter-Process Transport: Moves work-in-progress (WIP) automatically between different processes, workshops, or floors.

- Warehouse Automation: Interfaces with Automated Storage/Retrieval Systems (AS/RS) for hands-free pallet put-away and retrieval.

- Flexible Assembly Lines: Serves as a mobile assembly platform where products are built over multiple stations on the AGV itself.

- Finished Goods Handling & Palletizing: Automatically transports finished products to packaging or shipping areas.

How to Choose the Right AGV System for Your Factory

- Analyze Your Needs: Define material specs (size, weight), flow rate (cycle time), path complexity, and required docking precision.

- Assess the Environment: Consider floor conditions, slopes, areas of high human traffic, and spatial layout (aisle width, doors, elevators).

- Plan for System Integration: Evaluate compatibility with existing MES, ERP, or WMS systems and communication protocols (e.g., REST API, PLC interface).

- Select a Reliable Vendor: Assess the supplier’s technical expertise, industry-specific case studies, after-sales support, and Total Cost of Ownership (TCO).

- Implement in Phases: Start with a pilot project in a critical but contained area to demonstrate ROI and build internal expertise before scaling.

The Future: The Intelligent Evolution from AGVs to AMRs

The future of factory automation AGVs points toward smarter Autonomous Mobile Robots (AMRs). These next-generation vehicles will feature enhanced environmental perception, onboard intelligence, and fleet coordination capabilities. Integrated with 5G, the Industrial Internet of Things (IIoT), and Artificial Intelligence (AI), AGV/AMR fleets will enable dynamic task allocation, optimized real-time routing, and self-learning, evolving into the true “central intelligence” of factory logistics.

Conclusion

Investing in factory automation AGVs is more than purchasing “automated forklifts.” It’s a strategic upgrade to your internal logistics ecosystem and a critical step toward digital, transparent production and Industry 4.0. By implementing an AGV solution, manufacturers achieve immediate gains in operational efficiency and cost reduction while building the agile manufacturing capability needed to thrive in dynamic markets.

Start planning your AGV automation journey today and power your factory with intelligent movement.